Welcome to Open Lab

The facilities that we offer are capable of emulating different cardiac flows through different means. This page serves the purpose of explaining the uniqueness of the simulators that we have and what kind of of use they have.

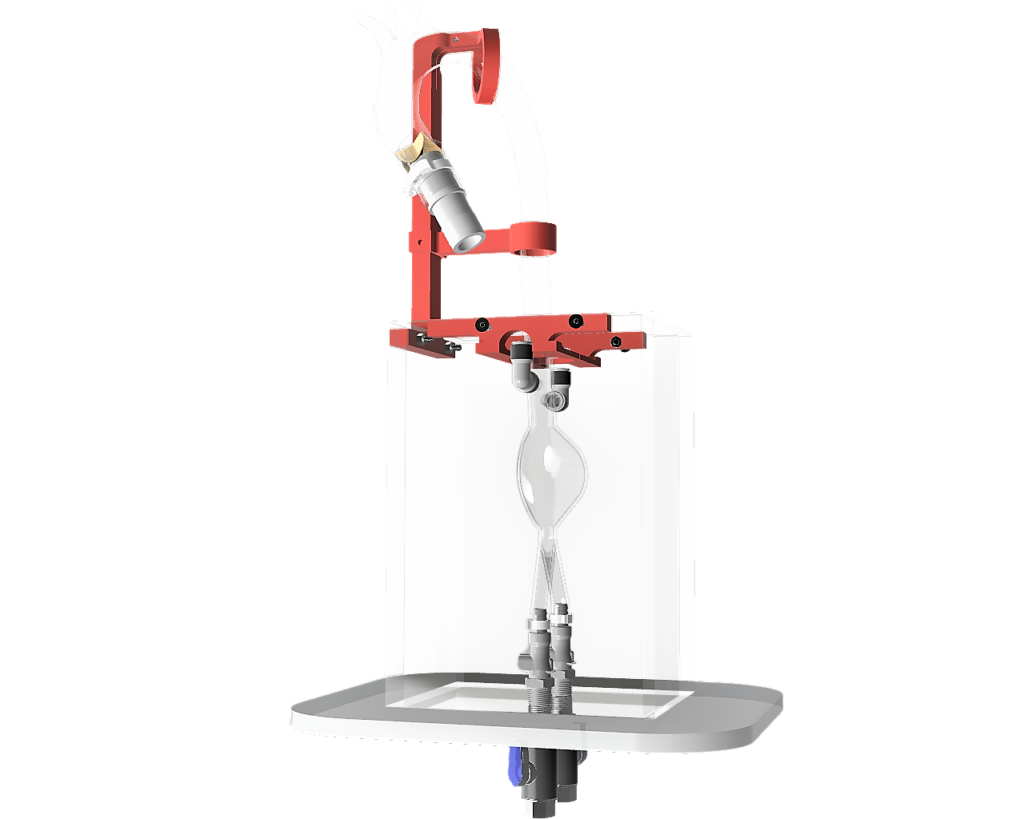

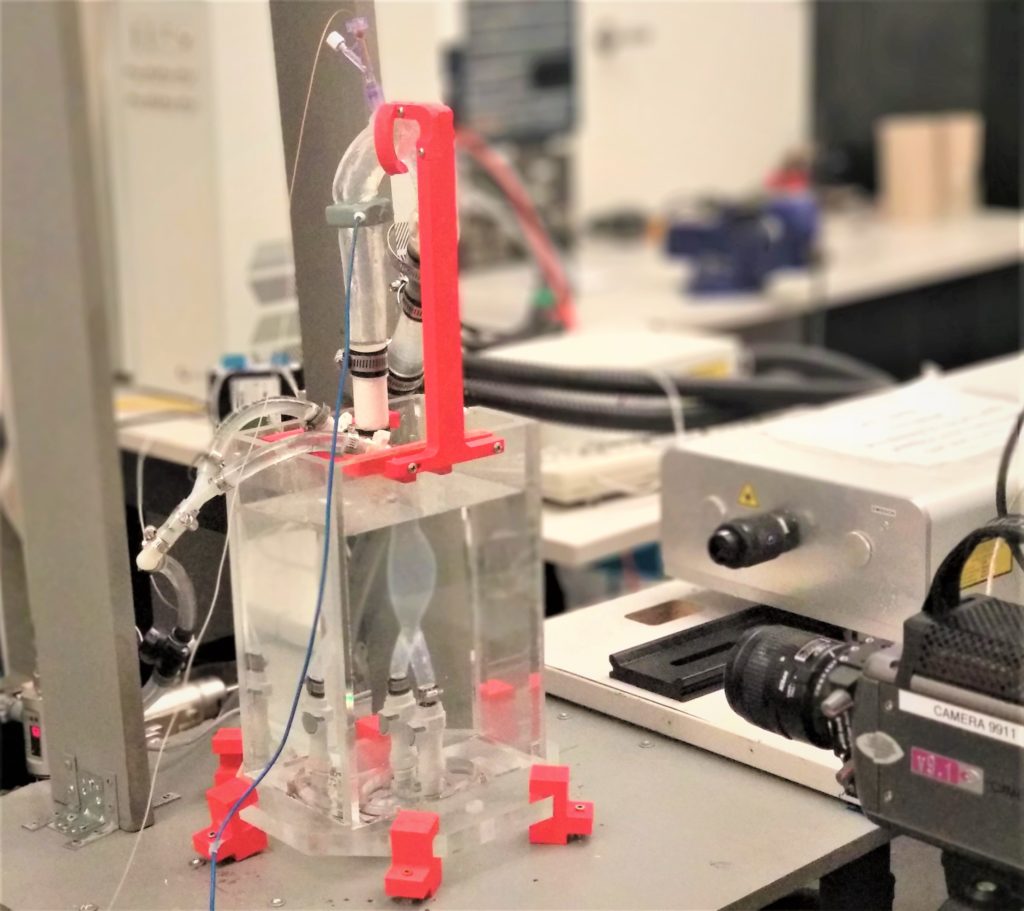

Particle image velocimetry (PIV) Setup

One of the most important measurement in studying fluid mechanics is the velocity field. Once a velocity field is obtained, further post-processing on the flow can help analyze different quantities. To explain the principle of PIV simply, the velocity field is measured by using the definition of velocity: a change of displacement over time. By tracking particles with a high frequency camera, velocity vectors can be assigned to windows that make the image (known as interrogation windows). To reduce the measurement error, a cross-correlation algorithm is used to track the most likely direction of particles that reside in an interrogation window. A high power laser is also used to generate a laser sheet to help track the position of particles. Overall, the measurement error of PIV is usually within 5%, making it quite accurate. Additionally, its ability to measure at high frame rates is quite desirable when compared to the resolution obtained in in vivo imaging techniques (i.e., echo doppler, MRI)

SIMULATION THROUGH IN-VITRO TESTING OF THE COMPLETE HEART (STITCH)

STITCH is our in-house heart duplicator, capable of simulating multiple cardiovascular pathologies (valvular disease such as aortic regurgitation, mitral regurgitation, mechanical heart valve obstruction to name a few). STITCH is capable of reproducing different flows by altering the flow rate (i.e., stroke volume), the compliance and the peripheral resistance. It is hydraulically actuated through the use of a linear motor. Data that can be measured include the instantaneous pressure, flow rate and the velocity field. Velocity field acquisition is obtained through particle image velocimetry (PIV) because of its high frame rate and low error (~5%).

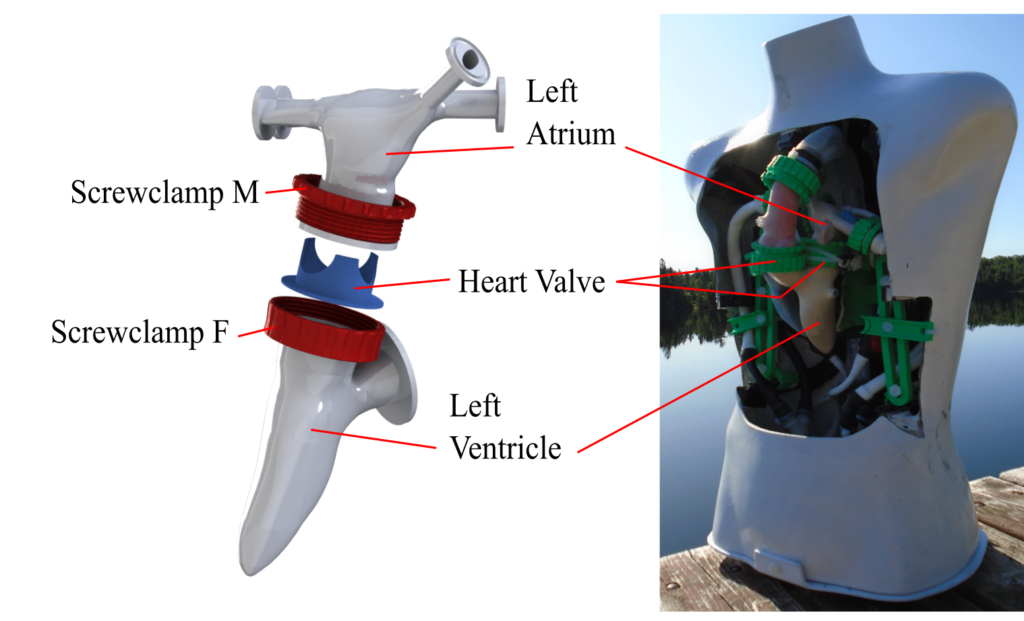

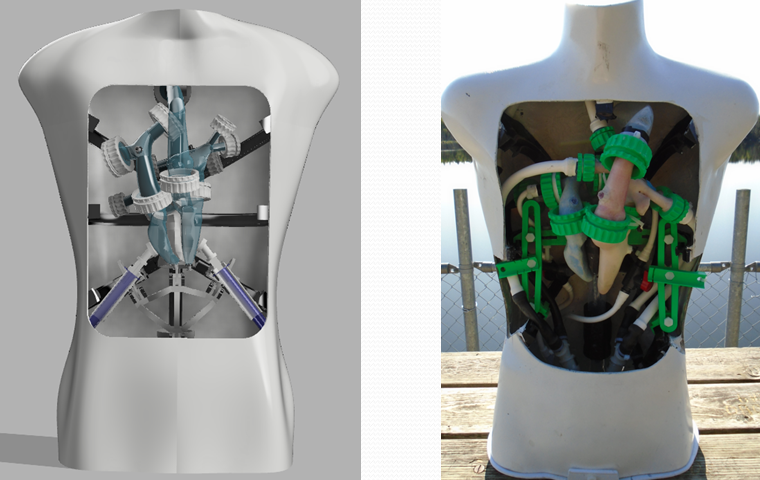

3D Printed patient specific cardiovascular simulator

The use of 3D printing has become very popular and affordable in the past few years. This has given the luxury of manufacturing complex three-dimensional parts that could not previously be manufactured in a traditional way. The 3D Printed patient specific cardiovascular simulator takes extensive advantage of this technology. After several iterations and multiple prototypes, the simulator is capable of replicating physiological pressures. Heart components are manufactured by using a flexible filament, NinjaFlex. NinjaFlex is used because of its elastic behavior, allowing the heart components to be compliant. Manufacturing of the components requires little effort in the manufacturing because of the 3D printing aspect. The most labor intensive aspect is to make the components leak free. Velocity field measurement on the mannequin were performed by using magnetic resonance imaging (MRI), which proved to be quite successful (see image below).

Abdominal aortic aneurysm (AAA) simulator

Abdominal aortic aneurysm is a vascular disorder characterized by a weakened aortic wall that results in a permanent expansion of the wall (by definition, it is when the diameter of the aorta exceeds 3 cm). AAA is usually asymptomatic, despite the danger it poses. An AAA simulator was built with the purpose of studying how the flow dynamics are affected by the change of geometry of the aorta (i.e., the presence of a bulge). The AAA simulator is capable of measuring instantaneous aortic pressure at the aortic root, flow rate and the velocity field. Velocity field acquisition is done through the use of particle image velocimetry.

Ongoing search towards counteracting aortic rupture (OSCAR)

Blunt traumatic aortic rupture (BTAR) is one of the leading cause of deaths following an automobile accident. Other causes also include sporting injuries (ball to chest) or free fall. The injury is characterized by a tear in the aorta, the largest artery in our body. The mortality rate for this injury is high if medical intervention is not received within adequate time. Despite its severity, the mechanism in which this injury occurs is still not very well understood. Some proposed mechanisms of failure include the osseous pinch, the water-hammer effect, an elevated hemodynamic pressure or a combination of stretching and twisting in the aorta. OSCAR was built with the intention of studying the flow dynamics in the aortic following a blunt injury. This in vitro simulation includes a track and a cart containing a silicone aorta with a biological heart valve. Actuated through the use of a pump, physiological aortic pressure waveforms are obtained. Additionally, OSCAR is capable of measuring the velocity field by using particle image velocimetry.

Pendulum In Vitro Impact Test on the Aorta (PIITA)

Similar to OSCAR, the pendulum in vitro impact test on the aorta was also designed with the purpose of studying blunt traumatic aortic rupture. PIITA was necessary to address some limitations in OSCAR. Limitations include the inertial effect on the pressure waveforms because of the accelerating cart, the inability to control the impact time and the transportability. PIITA was built around these constraints and the solution was to build a dummy. The dummy in question consists of a silicone aorta and ventricle with biological heart valves, protected by a 3D printed rib cage and a layer of ballistic gel. Impact is controlled through the use of a pendulum, which allows the impact and energy level to be controlled. Furthermore, because the movement now is from the pendulum instead of the cart, this results in a stationary dummy until the moment of impact. The primary measurements of PIITA are instantaneous pressure, flow rate and high FPS videos.