Linear System Lab - ELEC481

Magnetic Levitation Apparatus

ECP's unique MagLev apparatus dramatically demonstrates closed loop levitation of permanent and ferromagnetic elements. The apparatus includes laser feedback and high flux magnetics to affect large displacements and provide visually stimulating tracking and regulation demonstrations. The system is quickly set up in the open loop stable and unstable (repulsive and attractive fields) configurations shown. By adding a second magnet, two SIMO plants may be created, and by driving both actuators with both magnets, MIMO control is studied. The inherent magnetic field nonlinearities may be inverted via provided real-time algorithms for linear control study or the full system dynamics may be examined. Disturbances may be introduced via the second drive coil for demonstrating system regulation in SISO and SIMO operation

The field interaction between the two magnets causes strong cross coupling and thus produces a true multi-variable system. The inherent magnetic field nonlinearities may be inverted via provided real-time algorithms for linear control implementation or the full system dynamics may be studied.

This plant provides substantially more configuration flexibility and, by virtue of its dramatically greater levitation travel range, greater visual impact in demonstrations than any other educational maglev system.

This plant provides substantially more configuration flexibility and, by virtue of its dramatically greater levitation travel range, greater visual impact in demonstrations than any other educational maglev system.

A set of experiments are included with this system that provide for the identification of system dynamics and implement various linear and nonlinear control schemes for the SISO and MIMO plant configurations .

| Configurations | Six. The four SISO & MIMO shown plus 2 SIMO |

| Feedback | High resolution laser sensors |

| Actuator | High flux coils, rare-earth magnets |

| Range of Motion | 8 cm. peak, 4 cm. continuous, each magnet |

| Servo amplifiers | 1 KHz current loop bandwidth |

| Size, weight | 50x35x30 cm, 5.5kg. (20x14x12 in., 12lb.) |

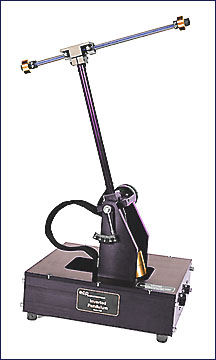

ECP Inverted Pendulum

This unique ECP design vividly demonstrates the need for and effectiveness of closed loop control. It is not the conventional rod-on-cart inverted pendulum, but rather steers a horizontal rod in the presence of gravity to balance and control the vertical rod. As detailed analytically in the manual, the plant has both right half plane poles and zeros as well as kinematic and gravitationally coupled nonlinearities. By adjusting mass properties, the characteristic roots may be varied to make the control problem range from being relatively simple to theoretically impossible!

This unique ECP design vividly demonstrates the need for and effectiveness of closed loop control. It is not the conventional rod-on-cart inverted pendulum, but rather steers a horizontal rod in the presence of gravity to balance and control the vertical rod. As detailed analytically in the manual, the plant has both right half plane poles and zeros as well as kinematic and gravitationally coupled nonlinearities. By adjusting mass properties, the characteristic roots may be varied to make the control problem range from being relatively simple to theoretically impossible!

The mechanism includes removable and adjustable moment-arm counter-weights on the vertical and horizontal rods for easy adjustment of plant dynamics. It features linear and rotary ball bearings at the joints for low friction and repeatable dynamic properties.

| Dynamic Frequencies | Poles adjustable 0.4 to 1.2 Hz |

| Feedback | High res. encoders, 16000 counts / rev. (theta) 12,800 counts / m (x) |

| Actuator | 0.6 N-m Fe-Co brush type |

| Servo amplifiers | 5 KHz current loop bandwidth |

| Size | 30x30x56 cm. (12x12x22in) |

This system is furnished with a set of experiments that provide for the identification of system dynamics and implement various control schemes for nonminimum phase and conditionally stable plants (right half plane poles and zeros).

Industrial Plant Emulator

The Industrial Emulator / Servo Trainer is ideal for studying control of practical systems in both the educational and industrial work places. A variety of features support the introduction and removal of non-ideal properties that are prevalent in real-world industrial applications. The mechanism provides for the easy adjustment of:

The Industrial Emulator / Servo Trainer is ideal for studying control of practical systems in both the educational and industrial work places. A variety of features support the introduction and removal of non-ideal properties that are prevalent in real-world industrial applications. The mechanism provides for the easy adjustment of:

- Drive and load inertias

- Gear ratio

- Disturbance torques (programmable)

- Viscous or Coulomb Friction

- Backlash

- Drive Flexibility

This system is furnished with a comprehensive set of experiments that provide an excellent introduction to applied control system fundamentals. It includes a special section on practical control implementation where the above non-ideal properties are studied and their effects mitigated through feedback control. Further experiments address practical issues such as sensor quantization, sample period, and drive saturation.

This system is furnished with a comprehensive set of experiments that provide an excellent introduction to applied control system fundamentals. It includes a special section on practical control implementation where the above non-ideal properties are studied and their effects mitigated through feedback control. Further experiments address practical issues such as sensor quantization, sample period, and drive saturation.

| No. Configurations | Six. Those shown plus two. SISO, SIMO, & MIMO (requires optional software) |

| Secondary Drive | Standard. Programmable disturbances - spatial & time varying plus viscous friction. MIMO operation |

| Actuator Inertia | Adjust.: .0004 to .0024 kg-m^2 |

| Load Inertia | Adjust.: .006 to .025 kg-m^2 |

| Gear Ratio | 6 speeds from 1.5:1 to 24:1 |

| Dynamic Freq's | Poles & zeros adjustable in range from 3 to 10 Hz. |

| Size | 30x30x51 cm (12x12x20 in) |

| Feedback | High res., 16,000 counts/rev. |

| Actuators (2) | 0.3 N-m contin., Fe-Co brushless |

| Servo Amp's (2) | 5 KHz current loop bandwidth |

Torsional Apparatus

The Model 205 apparatus is a highly versatile platform that is ideal for introductory undergraduate lab use and intermediate controls study. It has also been used extensively in advanced research. In its many possible configurations, this system represents a broad and important class of practical plants including: rigid bodies, flexibility in drives, and coupled discrete vibrating systems. It easily transforms into second, fourth, and sixth (optional) order plants with collocated or noncollocated sensor / actuator control. An optional secondary drive may be positioned at any output (disk) to create a MIMO plant (requires Executive USR® or RTWT/RTLT software) and provides for the study of disturbance rejection.

The Model 205 apparatus is a highly versatile platform that is ideal for introductory undergraduate lab use and intermediate controls study. It has also been used extensively in advanced research. In its many possible configurations, this system represents a broad and important class of practical plants including: rigid bodies, flexibility in drives, and coupled discrete vibrating systems. It easily transforms into second, fourth, and sixth (optional) order plants with collocated or noncollocated sensor / actuator control. An optional secondary drive may be positioned at any output (disk) to create a MIMO plant (requires Executive USR® or RTWT/RTLT software) and provides for the study of disturbance rejection.

The ability to readily adjust physical parameters such as inertia values and spring constants make it ideal for multiple student work group assignments. This apparatus closely follows its dynamic model and the theoretical predictions of open and closed loop behavior provided in the manual. It has proven to be highly robust and reliable in the field.

| Number of Unique Configurations | Six. Nine with optional 3rd inertia disk. Eighteen including MIMO using secondary drive accessory. |

| Inertia Adjustment | 10:1 |

| Spring Constant Adj. | 4:1 |

| Dynamic Frequencies | Poles & zeros adjustable in range from 0.8 to 7 Hz |

| Feedback | High res. encoders, 16000 counts/rev. |

| Actuator | 2.0 N-m Fe-Co brushless |

| Servo amplifiers | 5 KHz current loop bandwidth |

This system is furnished with a comprehensive set of experiments that provide an excellent introduction to applied control systems fundamentals and continue through flexible structure control.

Control Moment Gyroscope

E CP's four axis Control Moment Gyroscope is a dynamically rich system that provides superb demonstrations of multi-DOF rigid body control. Elementary experiments are readily performed that readily show the fascinating phenomenon of gyroscopic torque and its use in precision high authority control. More advanced topics range from MIMO linear control to fully general nonlinear control with singularity avoidance. Thus the system yields demonstrations that are intriguing to the layman and post-doctorate alike! In addition, the plant may be used to emulate the control of satellite attitude. Stimulating experiments first show the open loop nutation modes and then demonstrates their effective control.

E CP's four axis Control Moment Gyroscope is a dynamically rich system that provides superb demonstrations of multi-DOF rigid body control. Elementary experiments are readily performed that readily show the fascinating phenomenon of gyroscopic torque and its use in precision high authority control. More advanced topics range from MIMO linear control to fully general nonlinear control with singularity avoidance. Thus the system yields demonstrations that are intriguing to the layman and post-doctorate alike! In addition, the plant may be used to emulate the control of satellite attitude. Stimulating experiments first show the open loop nutation modes and then demonstrates their effective control.

The apparatus includes low friction slip rings at axes 3 and 4 for unlimited range of motion, and precision encoders for feedback of all position and velocity states. A host of safety features such as fail-safe brakes, inertial switches, and real-time watch-dog monitoring provide for safe operation of the apparatus.

.