The estimation of core losses is important in designing, uprating, and upgrading of electrical machines. Specifically, the need for highly efficient energy conversion devices with increasing high power density (frequency and magnetic loading), the accurate prediction of core losses is important. This requires state of the art core loss measurements, accurate core loss modeling, and application of the above to design and uprate studies.

a)

Measurements

Electric machine stator core and T-joints of three phase

transformers

are subjected to both pulsating and rotational fluxes. This requires

different

measurement methods and setups.

i. Pulsating

core loss measurements

Conventionally, core losses are measured using the Epstein, single sheet and toroid testers according to ASTM and IEC standards. These standards are specific to the type of the setup, flux density, and frequency measurement range.

PEER research

group has the capacity to measure both low and high

frequency (10 Hz to 4 kHz) core losses, on standard and non-standard

samples.

The test can be done under both sinusoidal and non-sinusoidal pulsating

fields.

|

|

|

|

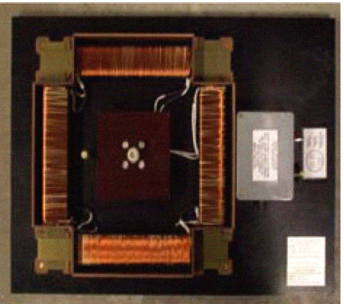

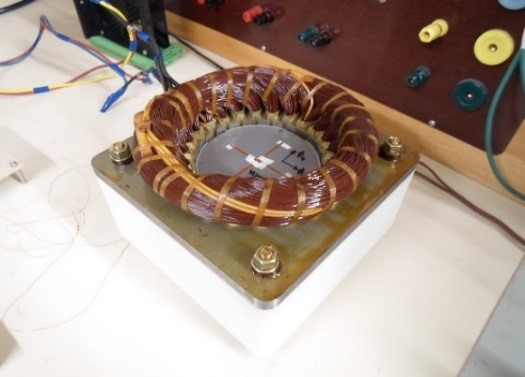

| (a) Toroid tester | (b) Single sheet tester | (c) Epstein frame | (d) Stator core toroid |

ii. Rotational

core loss measurements

Pulsating and rotational magnetizations differ in their loss mechanism. As such, they result in different core losses. The aspect-ratio, a ratio of the minimum to the maximum radii of a flux density locus is used to categorize magnetization into pulsating, elliptical and rotating. Aspect-ratios greater than zero (r > 0) are referred to as rotational.

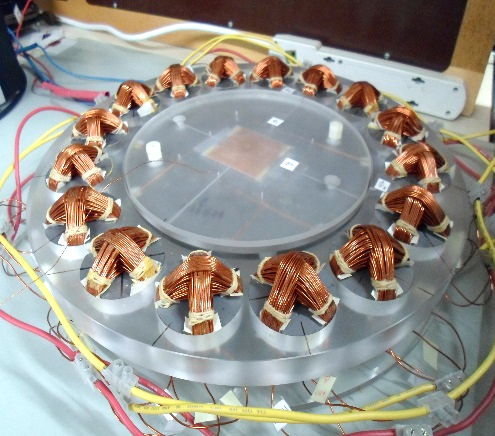

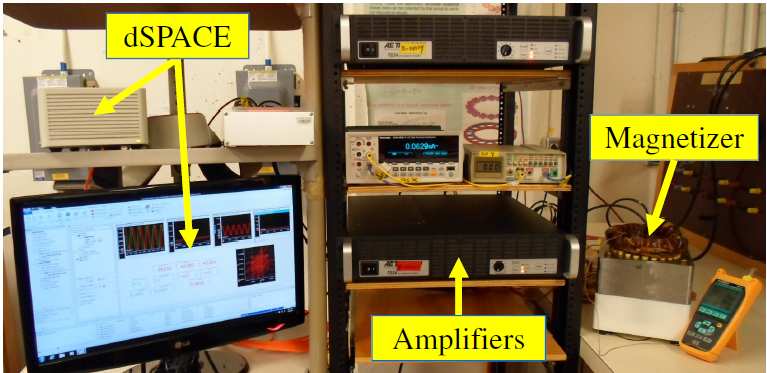

The PEER

research group has developed the capacity to measure rotational

core losses in the range of 60 Hz to 1 kHz, using the round rotational

single

sheet testers (RRSSTs) shown in

Figure (2).

Moreover, the stator-based RRSST can achieve

higher flux densities in the order of 2 T at 60 Hz.

|

|

|

| (a) Halbach RRSST | (b) Stator-based RRSST | (c) Rotational core loss measurement test bench |

Measurements are important in determining and initializing model parameters, and in the validation of the models.

b) Modelling

The classical

Steinmetz (two-term) and the three-term model coefficients

are usually determined from loss separation and curve fittings. These

coefficients are modified to extend their application to higher flux

densities

and frequencies. Results that are more accurate have been realized and

validated by considering the skin effect, minor loops, and the adoption

of the

energetic model. This has allowed the prediction of core losses under

both

sinusoidal and non-sinusoidal pulsating flux densities. This work is

being

extended to rotational core loss measurements.

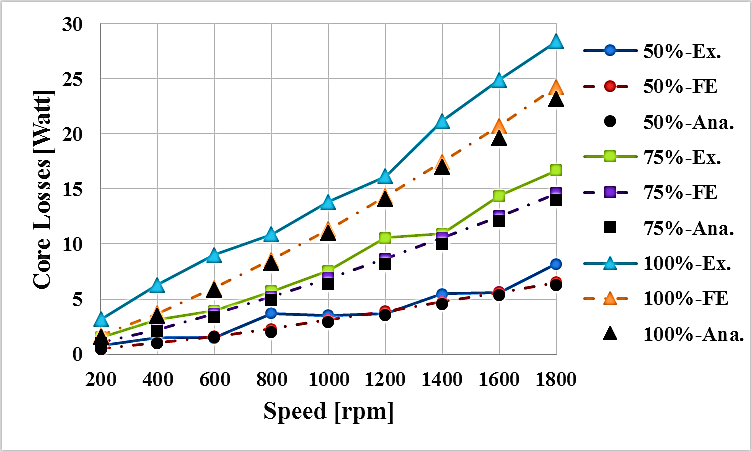

c) Applications

Core losses

have been analyzed in a variable flux PM machine, and some of

the results are shown in

Figure (3).

The inherent capability to demagnetize the

magnets allows the estimation of core losses in these machines,

analysis of the

build factors, switching schemes, and improvement of efficiency in the

flux-weakening region.

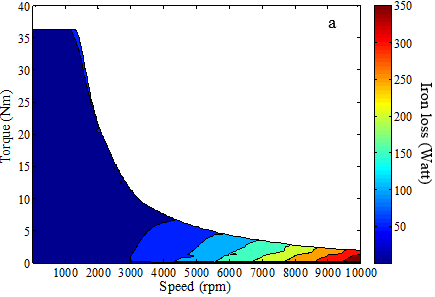

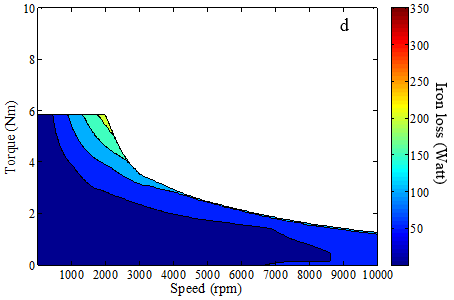

|

|

| (a) Rotor of the variable flux PM machine | (b)

Experimental, simulation and analytical core losses at different magnetization levels |

|

|

| (c) Core loss distribution in 100 % magnetization | (d) Core loss distribution in 25 % magnetization |

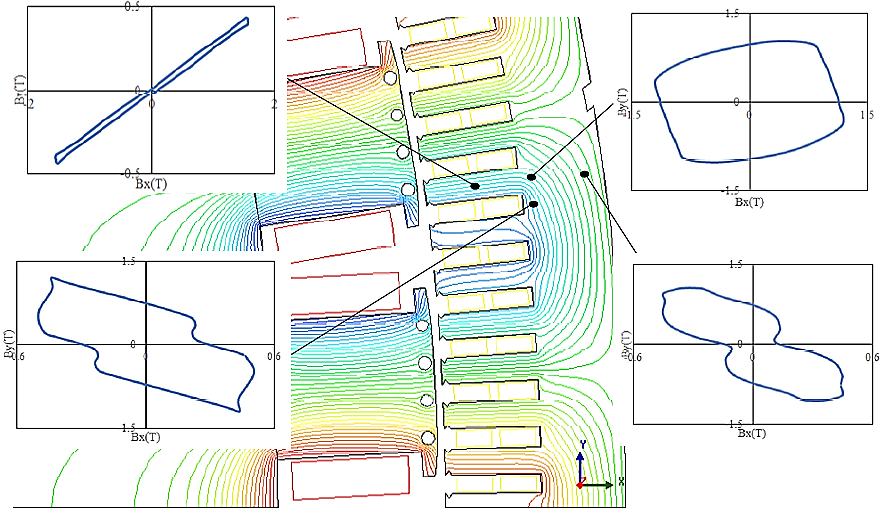

In addition, core losses are

invaluable in the uprating and

upgrading of

large MW rated machines, used in power generation and large mills such

as

cement factories. Increasing the rating of a machine requires the

accurate

prediction of hotspots - the potential failure locations. Hence,

rotational and

non-sinusoidal core loss measurements are imperative in uprating

studies. There

is ongoing research in the accurate prediction of core losses in the

uprating

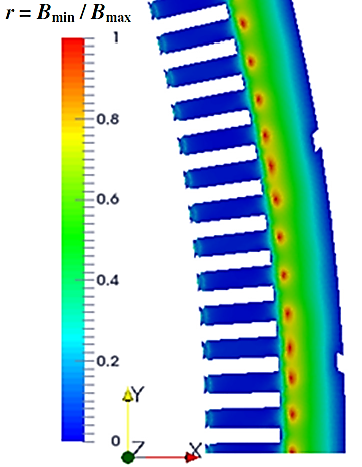

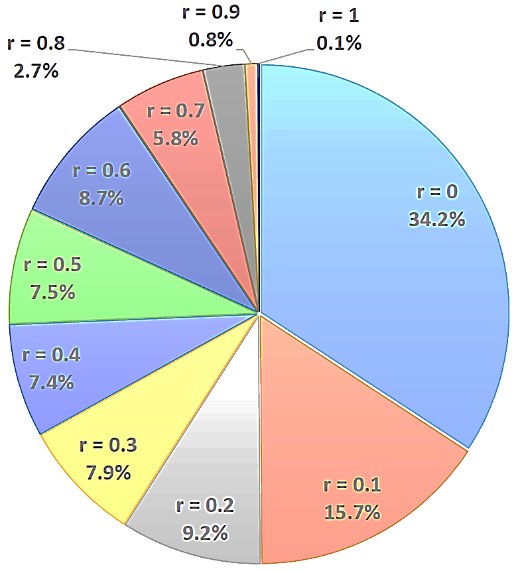

of a 19 MVA hydro generator. Figure (4) shows the presence of

non-sinusoidal pulsating

and rotational fields, and their distribution in the stator core this

hydro

generator. In addition, Figure (4) (c) shows that rotational zones are

greater

than 50 % in this stator core.

|

|

| (b) Aspect-ratio map | (c) Aspect-ratio percentage distribution |

In conclusion,

there is more work to be done in extending the

measurements to DC, higher frequencies and flux densities, under both

sinusoidal and non-sinusoidal flux densities. The application of core

losses in

machine design or any related study is challenging. This is because

they are

affected by other factors such as handling, type of cutting, stacking

pressure,

and other build factors that are difficult to model and test. Hence,

the

predicted and the measured core losses differ. There is room for more

research

in the consideration of build factors in terms of measurements,

modelling, and

application.