Ahmad Mostafa - Post Doc

Ahmadomar82 (Talk | contribs) |

Ahmadomar82 (Talk | contribs) |

||

| Line 47: | Line 47: | ||

*Expert in operating HITACHI-S3400 SEM equipped with EDS/WDS detectors. | *Expert in operating HITACHI-S3400 SEM equipped with EDS/WDS detectors. | ||

| − | * | + | *[https://publons.com/a/948918/ Verified Peer Reviewer]: |

- International Journal of Materials Research (formerly: Zeitschrift fuer Metallkunde) | - International Journal of Materials Research (formerly: Zeitschrift fuer Metallkunde) | ||

| Line 53: | Line 53: | ||

- Science and Engineering of Composites Materials | - Science and Engineering of Composites Materials | ||

| − | - [http://users.encs.concordia.ca/~tmg/images/f/f2/Certificate-reviewer-Dr.Mostafa.pdf MDPI-Metals] | + | - [http://users.encs.concordia.ca/~tmg/images/f/f2/Certificate-reviewer-Dr.Mostafa.pdf MDPI-Metals] |

| − | - [http://users.encs.concordia.ca/~tmg/images/f/f2/Certificate-reviewer-Dr.Mostafa.pdf MDPI-Materials] | + | - [http://users.encs.concordia.ca/~tmg/images/f/f2/Certificate-reviewer-Dr.Mostafa.pdf MDPI-Materials] |

*Expert in phase diagram investigation using: | *Expert in phase diagram investigation using: | ||

Revision as of 20:32, 29 July 2016

| Full name | Ahmad Omar Mostafa |

| a.mostafa[at]concordia.ca | |

| Room # | EV13.161 |

PhD with Materials Science background, published novel papers in materials science field, expert in alloy design and development, modeling and experimental investigation of metallic phase diagrams, advanced tooling design and manufacturing, and a reviewer for scientific journals. Have an extensive research collaboration, teaching and mentoring experience, extracurricular activities, and 5 years engineering experience in steel industry.

Contents |

Education

- 2015-present:

Postdoctorl Researcher, Mechanical and Materials Engineering Department, Masdar Institute of Science and Technology, Abu Dhabi, UAE.

- 2014-2015:

Postdoctorl Fellowship, Mechanical Engineering Department, Concordia University, Montreal, Canada.

- 2011-2014:

PhD Degree in Mechanical Engineering, under the supervision of Prof. Mamoun Medraj, Concordia University, Montreal, Canada.

- 2006 - 2009:

Masters Degree in Industrial engineering/Manufacturing and design under the supervision of Prof. Adnan Alkilani, Jordan University, Amman, Jordan.

- 2000 - 2004:

Bachelore Degree in Materials Engineering Technique, Technical College, Baghdad, Republic of Iraq.

Research Fields

- Additive manufacturing of IN718 superalloys

- Development of magnetic materials

- Alloys grain refinement

- Water erosion failure analysis

- Metal forming die design (Deep drawing and asymmetric angle extrusion dies)

- Atomic interdiffusion measurements of binary and ternary systems

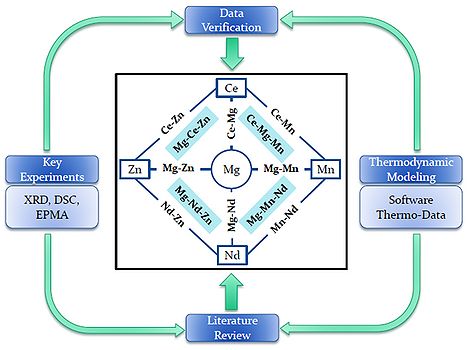

- Phase diagram investigation using computational thermodynamics coupled with key experiments as shown below:

Research Qualifications

- Expert in operating HITACHI-S3400 SEM equipped with EDS/WDS detectors.

- Verified Peer Reviewer:

- International Journal of Materials Research (formerly: Zeitschrift fuer Metallkunde)

- Science and Engineering of Composites Materials

- Expert in phase diagram investigation using:

- ICP

- DSC

- XRD

- XRF

- TEM

- FIB

- SEM, EDS and WDS

- Quartz tube sealing

- Induction and arc melting furnaces

- Atomic/Magnetic Force Microscopy (AFM/MFM)

- Very familiar with metal machining and cutting equipment, such as:

- Lathe machines (Concordia University approval)

- Milling machines (Concordia University approval)

- Shaping machines

- Water-jet cutting machine

- Passed Concordia University radiation safety exam

- Passed Concordia University corrosive materials safety training

- Passed Concordia University EDML safety exam

- Excellent cooperative with all group members from different topics

Research Work

- Postdoctoral Researcher, May 2015 - Present

Institute: Mechanical and Materials Engineering Department at Masdar Institute of Science and Technology

Projects: - Development of Magnetic Materials

- Phase diagrams of solar cell materials

- Additive manufacturing of SLM 3D printed IN718 superalloy

- Electric arc furnace dust (EAFD) management

- Postdoctoral fellow, August 2014 - 2015

Institute: Mechanical and Industrial Engineering Department at Concordia University.

Tasks: - Performing experimental and theoretical experiments on different phase diagrams

- Training and guiding the students in the thermodynamics of materials group (TMG)

- Reviewing students theses and publications

- PhD Thesis, January 2011 - May 2014

Institute: Mechanical and Industrial Engineering Department at Concordia University.

Thesis title: Experimental Investigation of the Phase Equilibria in the Mg-Mn-{Ce, Nd} and Ce-Mg-Zn Ternary Systems and Diffusivity Measurements of the Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} Binary Systems

Summary: In this work, the 450°C Mg-Mn-{Ce, Nd} and 300°C Ce-Mg-Zn isothermal sections were established using diffusion couples and key alloys. The phase relationships were determined using XDR, EDS/WDS and metallography. Diffusion couples were also used to measure the interdiffusion coefficients of the Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} binary systems based on the experimental composition profiles and Boltzmann-Matano method.

- MSc Thesis, September 2006 - September 2009

Institute: Industrial Engineering/Design and Manufacturing Department at Jordan University.

Thesis title: Effect of addition of Hf on the Mechanical Behavior and Wear Resistance of ZA5 Alloy

Summary: The ZA5 alloy melt solidifies with dendritic structure of large grain size, which affects its mechanical behavior and surface quality. This alloy is normally grain refined by some refiners like Titanium or Titanium+Boron additives. In this work, the effect of addition of hafnium (Hf) at different weight percentages, ranging from 0.02% to 0.12%, to ZA5 as a grain refiner on its micro structure, hardness, mechanical behavior and wear resistant, was investigated.

Published Works

Find me on: Scopus, Orcid, Google Scholar, LinkedIn, Research Gate, Publons

Journal Publications

[14] Adnan I. O. Zaid, Ali M. Othman, Ahmad O. Mostafa, "Scope of Utilization of a Hybrid System of Solar and Wind Energies as a Storage System in Palestine", International Journal of Science and Engineering Research (IJSER), 2016, 7 (7), 22-28.

[13] Adnan I. O. Zaid, Ahmad O. Mostafa, Ali M. Othman, "Utilization of Solar Energy as a Thermal Energy Storage System in Palestine", International Journal of Science and Engineering Research (IJSER), 2016, 7(6), 1083-1087.

[12] Adnan I. O. Zaid, Ahmad O. Mostafa, “Comparison between Mo Addition to Zinc Aluminum Alloy, ZA22, Grain Refined by Ti and Ti-B after Pressing by the Equal Channel Angular Press, ECAP”, International Journal of Science and Engineering Research (IJSER), 2016, 7(5), 1133-1138.

[11] Adnan I. O. Zaid, Safwan M. A. Al-qawabah, Ahmad O. Mostafa, “Effect of Mo Addition to ZA22 Alloy Grain Refined by Ti+B on its Metallurgical and Mechanical Characteristics after Pressing by the ECAP Process”, International Journal of Science and Engineering Research (IJSER), 2016, 7(5), 1128-1132.

[10] Dina Ma, Ahmad Mostafa, Dmytro Kevorkov, Pawel Jedrzejowski, Martin Pugh, Mamoun Medraj, "Water impingement erosion of deep rolled Ti64", Metals 2015, 5 (3), 1462-1486; doi:10.3390/met5031462. (Article Statistics)

[9] Ahmad Mostafa and Mamoun Medraj, "Experimental investigation of the Mg-Nd-Zn isothermal section at 300 ºC", Metals 2015, 5(1), 84-101; doi:10.3390/met5010084 (Article Statistics)

[8] T. Wang, D. Kevorkov, A. Mostafa, and M. Medraj, "Experimental investigation of the phase equilibria in the Al-Mn-Zn system at 400°C", Journal of Materials, vol. 2014, Article ID 451587, 13 pages, 2014. doi:10.1155/2014/451587

[7] A. Mostafa and M. Medraj, "On the atomic interdiffusion in Mg-{Ce,Nd,Zn} and Zn-{Ce,Nd} binary systems", Journal of Materials Research, 29(13), (2014) 1463-1479. (Article Statistics)

[6] Ahmad Mostafa, and Mamoun Medraj, "Phase Equilibria of the Ce-Mg-Zn Ternary System at 300 °C", Metals 2014, 4(2), 168-195; doi:10.3390/met4020168. (PDF version). (Article Statistics)

[5] Ahmad Mostafa, and Mamoun Medraj, "Experimental investigation of the Mg-Mn-Nd isothermal section at 450°C", Journal of Alloys and Compounds, 608 (2014) 247-257.

[4] Ahmad Mostafa, and Mamoun Medraj, "Experimental investigation of the Ce-Mg-Mn isothermal section at 723K (450°C) via diffusion couples technique", Metallurgical and Materials Transactions A, 45 (2014) 3144-3160. (Article Statistics)

[3] Md. Mezbahul Islam, Ahmad Mostafa, and Mamoun Medraj, "Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical Data", Journal of materials, Volume 2014 (2014), Article ID 704283, 33 pages. (PDF version)

[2] Md. I. Khan, A. Mostafa, M. Aljarrah, E. Essadiqi and M. Medraj, "Influence of cooling rate on microsegregation behavior of magnesium alloys", Journal of Materials, Volume 2014 (2014), Article ID 657647, 18 pages. (PDF version)

[1] A. Mostafa, A. E. Gheribi, M. Mezbahul-Islam, D. Kevrokov, and M. Medraj, Experimental Investigation and First-Principle Calculations Coupled with Thermodynamic Modeling of the Mn-Nd Phase Diagram, Calphad, 42 (2013) 27-37. (Article Statistics)

Refereed Conferences:

[3] Ignacio Picazo Rubio, Ahmad O. Mostafa, Vladimir Brailovski, Mohammad Jahazi, Mamoun Medraj, “Evaluation of microstructure and mechanical behavior of 3D printed Inconel 718 alloy”, in: Aerospace Engineering, UAEGRSC 16th, Al-Ain, UAE, April 2016.

[2] A. Mostafa, D. Kevorkov, A. Gheribi, M. Medraj, The Mg-Mn-Nd System: Experimental Investigation Coupled with Thermodynamic Modeling, ICMAA2012, 245-250.

[1] A.I.O Zaid and A.O. Mostafa, Effect of Addition of Hafnium (Hf) on the Mechanical Behavior and Wear Resistance of Zinc-Aluminum Alloy 5 (ZA5), ICPR 21st, May, 2011, Stuttgart, Germany.

Symposium Records:

[8] Ahmad Mostafa and Mamoun Medraj, Experimental investigation of the Ce-Mg-Mn isothermal section at 450°C via diffusion couples and key alloys techniques, MIE PhD Seminar Completion, Concordia University, Montreal, April 2014. Poster presentation

[7] Ahmad Mostafa and Mamoun Medraj, Experimental investigation of the Mg-{Mn,Zn}-{Ce-Nd} ternary phase diagrams, MagNET AGM, University of British Colombia, Vancouver, June 2013.Oral presentation.

[6] Ahmad Mostafa and Mamoun Medraj, Assessment of atomic interdiffusion of Mg and Nd in the Mg-Nd binary system, American Society of Metals (ASM) symposium, Montreal, February, 2013.Poster presentation.

[5] Ahmad Mostafa and Mamoun Medraj, Assessment of Atomic Interdiffusion of the Mg-Mn-Nd Ternary System and its Constituent Binaries, MagNET workshop IX, McGill University, Montreal, November, 2012. Poster Presentation.

[4] A. Mostafa, H. Alshahrani, K. Younes, S. Abdelkhalek, D. Ma, J. Ajaja, A. Karimi, and Y. Elshami, Design and Manufacturing of a Composites Seat, ECSGA Graduate Studend Poster Competition, Concordia University, Montreal, October, 2012. Poster presentation.

[3] A. Mostafa, A. E. Gheribi, D. Kevorkov, and M. Medraj, Isothermal Section of the Mg-Mn-Nd system at 450C: Experimental Investigation and Thermodynamic Modeling, MagNET AGM, Waterloo, June, 2012.Poster Presentation.

[2] A. Mostafa, D. Kevorkov, and M. Medraj, Experimental Investigation of Mg-Mn-Nd Phase Diagram, American Society of Metals (ASM) symposium, Montreal, April, 2012.Poster presentation.

[1] A. Mostafa, P. Ghosh, A. Pelton, and M. Medraj, Experimental Investigation and Thermodynamic Modeling of Mg-{Mn, Zn}-{Ce, Nd} Ternary systems, MagNET AGM, Vancouver, June, 2011.

Honors and Awards

- Nominated for the Governor General's Gold Medal Award 2015, by Mechanical and Industrial Engineering Department at Concordia University.

- Golden Key International Honour Society, Concordia University, Canada, September 2014.

- Nominated for the Governor General's Gold Medal Award 2014, by Mechanical and Industrial Engineering Department at Concordia University.

- Concordia Accelerator Award, Concordia University, April 2014.

- PhD Seminar Award by Mechanical and Industrial Engineering Department at Concordia University, March 2014.

- Nominated, by the School of Graduate Studies of Concordia University, for Graduate Certificate in University Teaching (UNIT) based on the excellent academic achievements (August, 2013)

- Concordia University Partial Tuition Scholarship for International Students (May 1, 2013 to April 30, 2014).

- Concordia University Partial Tuition Scholarship for International Students (September 1, 2012 to August 31, 2013).

- Best Poster Presentation Award, MagNET AGM, University of Waterloo, June, 2012.

- Concordia University Partial Tuition Scholarship for International Students (September 1, 2011 to August 31, 2012).

- University of Jordan. Excellent research student grant (2009), Amman, Jordan.

- Ministry of Higher Education. Excellent student award (2004), Baghdad, Iraq.

Teaching Experience

1- Winter Semester 2013/2014

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 321 (Properties and Failure of Materials) course.

2- Fall Semester 2013/2014

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 221 (Materials Science) course.

3- Winter Semester 2013:

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 321 (Properties and Failure of Materials) course.

4- Fall Semester 2012/2013

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 221 (Materials Science) course.

5- Winter Semester 2012:

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 321 (Properties and Failure of Materials) course.

6- From 1/10/2009 to 1/6/2010 (1st and 2nd semesters of 2009/2010):

Working for University of Jordan / Faculty of Engineering and Technology / Department of Industrial Engineering as an assistant teacher in the manufacturing processes laboratory. The taught topics involved: metal casting, wear of metals, mechanical behavior, rolling of metals, deep drawing, blanking and piercing of sheet metals, and extrusion of metals.

Work Experience

1- From 1/8/2009 to 12/01/2011:

Working for Qaraman Co. for Bolts and Spare Parts Ltd. as:

Manager of steel heat treatment department.

2- From 1/9/2007 to 1/7/2009:

Working for Al-Balqa for Metals and Tools Co. as:

i. Technical Manager with the following duties.

- Technical Support for BOHLER special steels (Steel selection & steel heat treatment).

- Marketing of BOHLER special steels.

3- From 1/7/2006 to 31/8/2007:

Working for Al-Hijaz Engineered Machining Establishment with its sister company (National Industrial Rehabilitation Company - NIRCO) as:

i. Marketing engineer of BELZONA products.

ii.Mechanical designer using AutoCAD.

4- From 20/11/2004 to 28/2/2006:

Working for SHEBA Metal Casting Company as:

i. Production engineer

ii. Heat treatment furnace operator.

iii. Patterns designe using AutoCAD software.

iv. Preparing daily reports explaining melting and heat-treatment procedures.