Ahmad Mostafa - Post Doc

Ahmadomar82 (Talk | contribs) (→Published Works) |

Ahmadomar82 (Talk | contribs) (→Published Works) |

||

| (334 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

{{Infobox.member | {{Infobox.member | ||

| − | |image = | + | |image = Personal photo-TTU.jpeg |

|fullname = Ahmad Omar Mostafa | |fullname = Ahmad Omar Mostafa | ||

| − | |email= | + | |email= a_mostaf[at]live.concordia.ca |

| − | | | + | |position= Assistant Professor |

}} | }} | ||

| − | + | Dr. Mostafa is currently an Associate Professor in the Mechanical Engineering Department at Tafila Technical University, Jordan. His PhD degree was obtained from Concordia University in Mechanical Engineering and focused on Materials Science. He published novel papers in materials science field, expert in alloy design and development, modeling and experimental investigation of metallic phase diagrams, advanced tooling design and manufacturing, and a [https://publons.com/author/948918/ahmad-mostafa#stats verified reviewer] for prestigious journals. Dr. Mostafa has an extensive research collaboration, teaching and mentoring experience, extracurricular activities, and 5 years engineering experience in steel industry. | |

== Education == | == Education == | ||

| − | *''' | + | *'''2015-2017''': |

| − | + | Postdoctorl Researcher, Mechanical and Materials Engineering Department, [http://www.masdar.ac.ae/ Masdar Institute of Science and Technology], Abu Dhabi, UAE. | |

| + | |||

| + | *'''2014-2015''': | ||

| + | |||

| + | Postdoctorl Fellowship, Mechanical Engineering Department, [http://www.concordia.ca/ Concordia University], Montreal, Canada. | ||

| + | |||

| + | *'''2011-2014''': | ||

| + | |||

| + | PhD Degree in Mechanical Engineering, under the supervision of Prof. Mamoun Medraj, [http://www.concordia.ca/ Concordia University], Montreal, Canada. | ||

*'''2006 - 2009''': | *'''2006 - 2009''': | ||

| − | Masters Degree in Industrial engineering/Manufacturing and design under the supervision of Prof. Adnan Alkilani, | + | Masters Degree in Industrial engineering/Manufacturing and design under the supervision of Prof. Adnan Alkilani, [http://www.ju.edu.jo Jordan University], Amman, Jordan. |

*'''2000 - 2004''': | *'''2000 - 2004''': | ||

| − | Bachelore Degree in Materials Engineering | + | Bachelore Degree in Materials Engineering Technique, [http://www.mtu.edu.iq/ Middle Technical University], Baghdad, Republic of Iraq. |

== Research Fields == | == Research Fields == | ||

| + | *Additive manufacturing of IN718 superalloys | ||

| + | *Development of magnetic materials | ||

*Alloys grain refinement | *Alloys grain refinement | ||

| − | *Metal forming die design (Deep drawing and asymmetric angle extrusion dies)<br> | + | *Water erosion failure analysis |

| − | *Atomic interdiffusion measurements of binary and ternary systems <br> | + | *Metal forming die design (Deep drawing and asymmetric angle extrusion dies)<br> |

| − | * | + | *Atomic interdiffusion measurements of binary and ternary systems <br> |

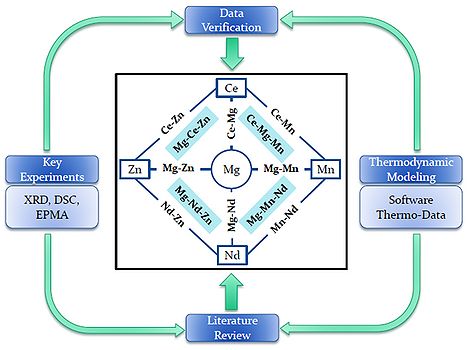

| + | *Phase diagram investigation using computational thermodynamics coupled with key experiments as shown below:<br> | ||

| + | *Polymer matrix composite materials:<br> | ||

| − | [[Image:Mg--Mn, Zn---Ce, Nd-.jpg|center|500x350px|Mg--Mn, Zn---Ce, Nd-.jpg]]<br> | + | [[Image:Mg--Mn, Zn---Ce, Nd-.jpg|center|500x350px|Mg--Mn, Zn---Ce, Nd-.jpg]]<br> |

| − | [[Image: | + | [[Image:Ahmad_SLM_IN718.jpg|center|550x551px|Ahmad_SLM_IN718.jpg]]<br> |

== Research Qualifications == | == Research Qualifications == | ||

| − | * | + | *Expert in operating HITACHI-S3400 SEM equipped with EDS/WDS detectors. |

| − | * | + | *[https://publons.com/a/948918/ Verified Peer Reviewer]: |

| − | + | ||

| − | - ICP<br> - DSC<br> - XRD <br> - SEM, EDS and WDS <br> - Quartz tube sealing<br> - Induction and arc melting furnaces <br> - Atomic/Magnetic Force Microscopy (AFM/MFM) | + | - Scientific Reports |

| + | |||

| + | - International Journal of Materials Research (formerly: Zeitschrift fuer Metallkunde) | ||

| + | |||

| + | - Journal of Materials and Design (JMAD) | ||

| + | |||

| + | - Science and Engineering of Composites Materials | ||

| + | |||

| + | - [http://users.encs.concordia.ca/~tmg/images/f/f2/Certificate-reviewer-Dr.Mostafa.pdf MDPI-Metals] | ||

| + | |||

| + | - [http://users.encs.concordia.ca/~tmg/images/f/f2/Certificate-reviewer-Dr.Mostafa.pdf MDPI-Materials] | ||

| + | |||

| + | *Expert in phase diagram investigation using: | ||

| + | |||

| + | - ICP<br> - DSC<br> - XRD<br> - XRF<br> - TEM<br> - FIB<br> - SEM, EBSD, EDS and WDS <br> - Quartz tube sealing<br> - Induction and arc melting furnaces <br> - Atomic/Magnetic Force Microscopy (AFM/MFM) | ||

*Very familiar with metal machining and cutting equipment, such as: | *Very familiar with metal machining and cutting equipment, such as: | ||

| Line 51: | Line 76: | ||

*Passed Concordia University EDML safety exam | *Passed Concordia University EDML safety exam | ||

*Excellent cooperative with all group members from different topics | *Excellent cooperative with all group members from different topics | ||

| + | |||

| + | == Research Work == | ||

| + | |||

| + | |||

| + | *'''''Associate Professor''''', September 2022- Present | ||

| + | |||

| + | <font color="red">'''Affiliation'''</font>: Mechanical Engineering Department at Tafila Technical University | ||

| + | |||

| + | <font color="red">'''Projects'''</font>: - Effect of grain refiners on the mechanical properties of Al and Zn alloys | ||

| + | |||

| + | - Phase diagrams | ||

| + | |||

| + | - Additive manufacturing | ||

| + | |||

| + | - Electric arc furnace dust (EAFD) Analysis | ||

| + | |||

| + | <br> | ||

| + | |||

| + | *'''''Assistant Professor''''', September 2017 - September 2022 | ||

| + | |||

| + | <font color="red">'''Affiliation'''</font>: Mechanical Engineering Department at Tafila Technical University | ||

| + | |||

| + | <font color="red">'''Projects'''</font>: - Effect of grain refiners on the mechanical properties of Al and Zn alloys | ||

| + | |||

| + | - Phase diagrams | ||

| + | |||

| + | - Additive manufacturing | ||

| + | |||

| + | - Electric arc furnace dust (EAFD) Analysis | ||

| + | |||

| + | <br> | ||

| + | |||

| + | *'''''Postdoctoral Researcher''''', May 2015 - August 2017 | ||

| + | |||

| + | <font color="red">'''Affiliation'''</font>: Mechanical and Materials Engineering Department at Masdar Institute of Science and Technology | ||

| + | |||

| + | <font color="red">'''Projects'''</font>: - Development of Magnetic Materials | ||

| + | |||

| + | - Phase diagrams of solar cell materials | ||

| + | |||

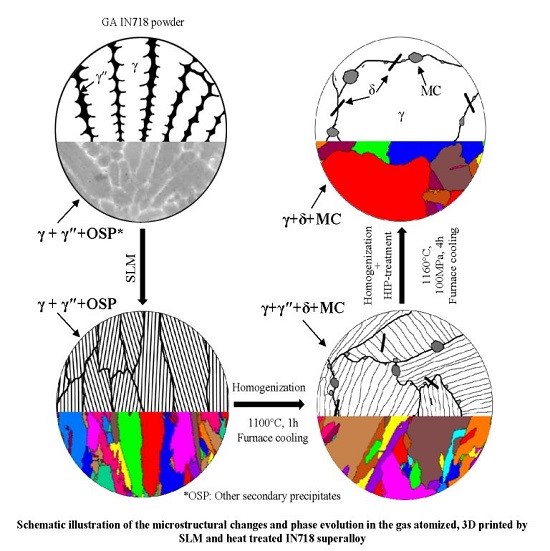

| + | - Additive manufacturing of SLM 3D printed IN718 superalloy | ||

| + | |||

| + | - Electric arc furnace dust (EAFD) management | ||

| + | |||

| + | <br> | ||

| + | |||

| + | *'''''Postdoctoral fellow''''', August 2014 - May 2015 | ||

| + | |||

| + | <font color="red">'''Affiliation'''</font>: Mechanical and Industrial Engineering Department at Concordia University. | ||

| + | |||

| + | <font color="red">'''Tasks'''</font>: - Performing experimental and theoretical experiments on different phase diagrams | ||

| + | |||

| + | - Training and guiding the students in the thermodynamics of materials group (TMG) | ||

| + | |||

| + | - Reviewing students theses and publications | ||

| + | |||

| + | <br> | ||

| + | |||

| + | *[http://spectrum.library.concordia.ca/978654/ '''''PhD Thesis, '''''] January 2011 - May 2014 | ||

| + | |||

| + | <font color="red">'''Affiliation'''</font>: Mechanical and Industrial Engineering Department at Concordia University. | ||

| + | |||

| + | <font color="red">'''Thesis title'''</font>: Experimental Investigation of the Phase Equilibria in the Mg-Mn-{Ce, Nd} and Ce-Mg-Zn Ternary Systems and Diffusivity Measurements of the Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} Binary Systems | ||

| + | |||

| + | <font color="red">'''Summary'''</font>: In this work, the 450°C Mg-Mn-{Ce, Nd} and 300°C Ce-Mg-Zn isothermal sections were established using diffusion couples and key alloys. The phase relationships were determined using XDR, EDS/WDS and metallography. Diffusion couples were also used to measure the interdiffusion coefficients of the Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} binary systems based on the experimental composition profiles and Boltzmann-Matano method. | ||

| + | |||

| + | <br> | ||

| + | |||

| + | *[http://dspace.ju.edu.jo/xmlui/handle/123456789/10895 '''''MSc Thesis,'''''] September 2006 - September 2009 | ||

| + | |||

| + | <font color="red">'''Affiliation'''</font>: Industrial Engineering/Design and Manufacturing Department at Jordan University. | ||

| + | |||

| + | <font color="red">'''Thesis title'''</font>: Effect of addition of Hf on the Mechanical Behavior and Wear Resistance of ZA5 Alloy | ||

| + | |||

| + | <font color="red">'''Summary'''</font>: The ZA5 alloy melt solidifies with dendritic structure of large grain size, which affects its mechanical behavior and surface quality. This alloy is normally grain refined by some refiners like Titanium or Titanium+Boron additives. In this work, the effect of addition of hafnium (Hf) at different weight percentages, ranging from 0.02% to 0.12%, to ZA5 as a grain refiner on its micro structure, hardness, mechanical behavior and wear resistant, was investigated. | ||

== Published Works == | == Published Works == | ||

| + | |||

| + | <sup>Find me on: </sup>[http://www.scopus.com/inward/authorDetails.url?authorID=55751744933&partnerID=MN8TOARS <sup>Scopus</sup>]<sup>, </sup>[http://orcid.org/0000-0001-5625-1106 <sup>Orcid</sup>]<sup>, </sup>[http://scholar.google.ca/citations?user=HTMIr8UAAAAJ&hl=en <sup>Google Scholar</sup>]<sup>, </sup><sup>[https://www.linkedin.com/in/ahmad-mostafa-phd-63927035 LinkedIn], [https://www.researchgate.net/profile/Ahmad_Mostafa7 Research Gate], [https://www.webofscience.com/wos/author/record/J-7600-2013 WOS], [https://www.youtube.com/channel/UCBRXTcqbe1mb1uvmpwlT5qQ/videos YouTube</sup>], <sup>[https://www.growkudos.com/profile/ahmad_mostafa KUDOS], </sup><sup>[https://www.semanticscholar.org/author/Ahmad-Mostafa/145234630 Semantic Scholar] | ||

'''''Journal Publications''''' | '''''Journal Publications''''' | ||

| − | [ | + | [35] Mostafa, Ahmad Omar. "[https://www.igi-global.com/gateway/chapter/352008#pnlRecommendationForm Navigating Joining Challenges in Friction Stir Welding of Hybrid Composite Structures] ." Utilizing Friction Stir Techniques for Composite Hybridization. IGI Global, 2024. 382-406. DOI: 10.4018/979-8-3693-3993-0.ch018 |

| − | [ | + | [34] KY Eayal Awwad, Khosro Fallahnezhad, BF Yousif, Ahmad Mostafa, Omar Alajarmeh, A Shalwan, Xuesen Zeng, "[https://link.springer.com/content/pdf/10.1007/s40544-023-0795-x.pdf Finite element analysis and experimental validation of polymer–metal contacts in block-on-ring configuration]", Friction, 2024, 12, 3, pp. 554-568. doi: 10.1007/s40544-023-0795-x. |

| − | [ | + | [33] Hanan Saleet , Alaa Aldamsah, Mohamad Banikhaled, Ayman Abu-Baker, Rebhi A. Damseh, Ma’moun Al-Smadi, Ahmad Mostafa, Wael Adaileh, Ali Alahmer, Ahmed Al-Salaymeh, Sara Al Twassi, Rasha AlBeek and Kholoud Hassouneh, "[https://doi.org/10.3390/wevj14090232 Importance and Barriers of Establishing Educational/Training Programs in Electric Vehicles/Hybrid-Electric Vehicles in Jordan]", World Electric Vehicle Journal, 2023, 14(9), 232. doi:10.3390/wevj14090232 |

| + | [32] W Adaileh, R Alhdayat, A Mostafa, "[http://utilitasmathematica.com/index.php/Index/article/view/1662 Selection of material and process for a brake pad using CES software]", Utilitas Mathematica 120, 356-367. | ||

| + | [31] K. Y. Eayal Awwad, B. F. Yousif, Ahmad Mostafa, Omar Alajarmeh, and Xuesen Zeng, "[https://doi.org/10.1177/07316844221143451 Tribological and mechanical performances of newly developed eco-epoxy composites incorporating flax fibres and graphene nanoplatelets]", Journal of Reinforced Plastics and Composites, 2023;42(17-18):939-952. doi:10.1177/07316844221143451 | ||

| − | '' | + | [30] Ahmad Mostafa and Nabeel Alshabatat, "[https://www.mdpi.com/1637114 Microstructural, Mechanical and Wear Properties of Al–1.3%Si Alloy as Compared to Hypo/ Hyper–Eutectic Compositions in Al–Si Alloy System]", Crystals 2022, 12(5), 719; https://doi.org/10.3390/cryst12050719. |

| + | |||

| + | [29] Alahmer, A.; Rezk, H.; Aladayleh, W.; Mostafa, A.O.; Abu-Zaid, M.; Alahmer, H.; Gomaa, M.R.; Alhussan, A.A.; Ghoniem, R.M. Modeling and Optimization of a Compression "Ignition Engine Fueled with Biodiesel Blends for Performance Improvement", Mathematics 2022, 10(3), 420; https://doi.org/10.3390/math10030420. | ||

| + | |||

| + | [28] M. Sadeghi Gogheri, M. Kasiri-Asgarani, H. Reza Bakhsheshi-Rad, H. Ghayour, M. Rafiei, A. Mostafa, F. Berto, "[https://doi.org/10.1016/j.engfailanal.2021.105799 Friction welding of pure titanium-AZ31 magnesium alloy: Characterization and simulation]", Eng. Fail. Anal. (2022) 105799. doi:10.1016/j.engfailanal.2021.105799. | ||

| + | |||

| + | [27] Alahmer, A.; Al-Amayreh, M.; Mostafa, A.O.; Al-Dabbas, M.; Rezk, H. "[https://www.mdpi.com/1996-1073/14/15/4662 Magnetic Refrigeration Design Technologies: State of the Art and General Perspectives]". Energies 2021, 14, 4662. DOI:10.3390/en14154662 | ||

| + | |||

| + | [26] A. Mostafa, W. Adaileh, A. Awad, A. Kilani, "[https://doi.org/10.3390/cryst11030270 Mechanical Properties of Commercial Purity Aluminum Modified by Zirconium Micro‐Additives]". Crystals 2021, 11, 270. DOI:10.3390/cryst11030270 | ||

| + | |||

| + | [25] S. Al-Qawabah, A. Mostafa, A. Al-Rawajfeh, U. Al-Qawabeha, "[http://mit.imt.si/izvodi/mit206/al-qawabah.pdf Effect of Heat Treatment on the Grain Size, Microhardness and Corrosion Behavior of the Cold-Working Tool Steels AISI D2 and AISI O1]", MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY, 2020, Vol. 54, issue 6, pp 785–790. DOI:10.17222/mit.2020.035 | ||

| + | |||

| + | [24] L. Hai Tat, H. R. Bakhsheshi-Rad, E. Hamzah, M.H. Cho, A. Mostafa, S. Farahany, "[https://doi.org/10.1080/02670836.2019.1705587 Microstructure, phase evolution and corrosion behavior of the Zn-Al-Mg-Sb coated alloys]", Materials Science and Technology, 2020, vol 36, issue 3, pp 353-366. DOI:10.1080/02670836.2019.1705587. | ||

| + | |||

| + | [23] Shaheen Anis, Ahmad Mostafa, Nidal Hilal, Raed Hashaikeh, "[https://doi.org/10.1007/s11661-019-05596-0 Nanocrystalline NiWO4-WO3-WO2.9 Composite strings: Fabrication, Characterization and their Electrocatalytic Performance for Hydrogen Evolution Reaction]", Metallurgical and Materials Transactions A, 2020, vol 51, issue 3, pp 1264–1274. DOI:10.1007/s11661-019-05596-0. | ||

| + | |||

| + | [22] Ahmad Mostafa, Ubeidallah Al-Qawabeh, Audai Al-Akailah, "[http://www.ahu.edu.jo/ahuj/Issues/1040182_%D8%A7%D9%84%D8%B9%D8%AF_%201%20%D8%A7%D9%84%D9%85%D8%AC%D9%84%D8%AF%201-2019_18_6_2019.pdf Grain refinement of cast Zamak 5 alloy by 0.1, 0.2 and 0.5 wt.% Mn]", Al-Hussein Bin Talal's University Journal of Research, 2019, Vol 1, Issue 1, pp 1-15. | ||

| + | |||

| + | [21] Ahmad Mostafa, "[https://www.igi-global.com/gateway/article/227705 Mechanical Properties and Wear Behavior of Aluminum Grain Refined by Ti and Ti+B] ", ''International Journal of Surface Engineering and Interdisciplinary Materials Science'', 2019, 7(1), pp 1-19. DOI:10.4018/IJSEIMS.2019010101 | ||

| + | |||

| + | [20] Raiyan Seede, Ahmad Mostafa, Vladimir Brailovski, Mohammad Jahazi and Mamoun Medraj, “[http://www.mdpi.com/2504-4494/2/2/30 Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases]”, Manufacturing and Materials Processing, 2018, 2, 30. DOI:10.3390/jmmp2020030 | ||

| + | |||

| + | [19] Ahmad Mostafa, Mohamed Shahtout, Tariq Al Afeefi and Mamoun Medraj, "[https://doi.org/10.4028/www.scientific.net/KEM.765.73 Conversion of Electric Arc Furnace Dust into Ceramics Using Thermodynamic Calculations and Experimental Work]", ''Key Engineering Materials'' (ISSN: 1662-9795), 2018, 765, pp 73-78. DOI:10.4028/www.scientific.net/KEM.765.73 | ||

| + | |||

| + | [18] Ahmad Mostafa, Davood Shahriari, Ignacio Picazo Rubio, Vladimir Brailovski, Mohammad Jahazi and Mamoun Medraj, "[https://doi.org/10.1007/s00170-017-1522-4 Hot compression behavior andmicrostructure of selectively laser-melted IN718 alloy]", ''The International Journal of Advanced Manufacturing Technology'', 2018, 96, 371. DOI:10.1007/s00170-017-1522-4 | ||

| + | |||

| + | [17] Ahmad Mostafa، Mamoun Medraj, "[http://dx.doi.org/10.3390/ma10060676 Binary phase diagrams and thermodynamic properties of silicon and essential doping elements (Al, As, B, Bi, Ga, In, N, P, Sb and Tl)]", ''Materials'', 2017, 10(6), 676. DOI:10.3390/ma10060676 | ||

| + | |||

| + | [16] Ahmad Mostafa , Ignacio Picazo Rubio , Vladimir Brailovski , Mohammad Jahazi , Mamoun Medraj, "[http://dx.doi.org/10.3390/met7060196 Structure, texture and phases in 3D printed IN718 alloy subjected to homogenization and HIP treatments]", ''Metals'', 2017, 7(6), 196. DOI:10.3390/met7060196 | ||

| + | |||

| + | [15] Bolarinwa Komolafe, Ahmad Mostafa, [https://doi.org/10.1088/2053-1591/aa7311 "Wetting and spreading behaviour of Ti-based brazing filler on Ti64 substrate"], ''Materials Research Express'', 2017, 6(4), 066503. DOI:10.1088/2053-1591/aa7311 | ||

| + | |||

| + | [14] Adnan I. O. Zaid, Ahmad Mostafa, "[http://dx.doi.org/10.5185/amlett.2017.1662 Effect of Hafnium Addition on Wear Resistance of Zinc-Aluminum 5 Alloy: a Three-Dimensional Presentation]", ''Advanced Materials Letters'', 2017, Vol 8, Issue 9, pp 910-915. DOI:10.5185/amlett.2017.1662 | ||

| + | |||

| + | [13] Shaheen F Anis, Boor S Lalia, Ahmad O Mostafa, Raed Hashaikeh, [http://rdcu.be/qig9 “Electrospun Nickel-Tungsten Oxide Composite Fibers as Active Electrocatalysts for Hydrogen Evolution Reaction”], ''Journal of Materials Science''', 52(12):7269–7281. DOI:10.1007/s10853-017-0964-2 | ||

| + | |||

| + | [12] H.R. Bakhsheshi-Rada, E. Hamzah, S.L. Joy Yii, A. Mostafa, R. Ebrahimi-Kahrizsangi, M. Medraj, [http://www.tandfonline.com/doi/full/10.1080/02670836.2017.1288777 “Characterization and thermodynamic calculations of biodegradable Mg-2.2Zn-3.7Ce and Mg-Ca-2.2Zn-3.7Ce alloys”], ''Materials Science and Technology'', 2017, 33(11), pp 1333-1345. DOI: 10.1080/02670836.2017.1288777 | ||

| + | |||

| + | [11] H. Bakhsheshi, E. Hamzah, H. Low, M. Cho, M. Kasiri, S. Farahany, A. Mostafa, M. Medraj, “[http://link.springer.com/article/10.1007/s40195-017-0534-2 Thermal characteristics, mechanical properties, in-vitro degradation and cytotoxicity of novel biodegradable Zn-Al-Mg and Zn-Al-Mg-xBi alloys]”, ''Acta Metallurgica Sinica (English letters)'', Volume 30, Issue 3, pp 201–211. DOI: 10.1007/s40195-017-0534-2 | ||

| + | |||

| + | [10] Dina Ma, Ahmad Mostafa, Dmytro Kevorkov, Pawel Jedrzejowski, Martin Pugh, Mamoun Medraj, [http://dx.doi.org/10.3390/met5031462 "Water impingement erosion of deep rolled Ti64"], ''Metals'' 2015, 5 (3), 1462-1486; doi:10.3390/met5031462. [http://www.mdpi.com/2075-4701/5/3/1462#stats (<font color="green"><u>''Article Statistics''</u></font>)] | ||

| + | |||

| + | [9] Ahmad Mostafa and Mamoun Medraj, [http://www.mdpi.com/2075-4701/5/1/84 "Experimental investigation of the Mg-Nd-Zn isothermal section at 300 ºC"], ''Metals'' 2015, 5(1), 84-101; doi:10.3390/met5010084 [http://www.mdpi.com/2075-4701/5/1/84#stats (<font color="green"><u>''Article Statistics''</u></font>)] | ||

| + | |||

| + | [8] T. Wang, D. Kevorkov, A. Mostafa, and M. Medraj, "[http://www.hindawi.com/journals/jma/aip/451587/ Experimental investigation of the phase equilibria in the Al-Mn-Zn system at 400°C]", ''Journal of Materials'', vol. 2014, Article ID 451587, 13 pages, 2014. doi:10.1155/2014/451587 | ||

| + | |||

| + | [7] A. Mostafa and M. Medraj, "[http://dx.doi.org/10.1557/jmr.2014.153 On the atomic interdiffusion in Mg-{Ce,Nd,Zn} and Zn-{Ce,Nd} binary systems]", ''Journal of Materials Research'', 29(13), (2014) 1463-1479. [http://www.altmetric.com/details.php?domain=journals.cambridge.org&doi=10.1557/jmr.2014.153 (<font color="green"><u>''Article Statistics''</u></font>)] | ||

| + | |||

| + | [6] Ahmad Mostafa, and Mamoun Medraj, [http://dx.doi.org/10.3390/met4020168 "Phase Equilibria of the Ce-Mg-Zn Ternary System at 300 °C"], ''Metals'' 2014, 4(2), 168-195; doi:10.3390/met4020168. [http://users.encs.concordia.ca/~tmg/images/7/7c/Metals-04-00168.pdf (PDF version)]. [http://www.mdpi.com/2075-4701/4/2/168#stats (<font color="green"><u>''Article Statistics''</u></font>)] | ||

| + | |||

| + | [5] Ahmad Mostafa, and Mamoun Medraj, [http://dx.doi.org/10.1016/j.jallcom.2014.04.113 "Experimental investigation of the Mg-Mn-Nd isothermal section at 450°C"], ''Journal of Alloys and Compounds'', 608 (2014) 247-257. | ||

| + | |||

| + | [4] Ahmad Mostafa, and Mamoun Medraj, [http://link.springer.com/article/10.1007/s11661-014-2251-z "Experimental investigation of the Ce-Mg-Mn isothermal section at 723K (450°C) via diffusion couples technique"], ''Metallurgical and Materials Transactions A'', 45 (2014) 3144-3160. [http://www.altmetric.com/details.php?citation_id=2522522 (<font color="green"><u>''Article Statistics''</u></font>)] | ||

| + | |||

| + | [3] Md. Mezbahul Islam, Ahmad Mostafa, and Mamoun Medraj, "[http://www.hindawi.com/journals/jma/aip/704283/ Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical Data]", ''Journal of materials'', Volume 2014 (2014), Article ID 704283, 33 pages. [http://users.encs.concordia.ca/~tmg/images/1/1d/704283_%282%29.pdf (PDF version)] | ||

| + | |||

| + | [2] Md. I. Khan, A. Mostafa, M. Aljarrah, E. Essadiqi and M. Medraj, "[http://dx.doi.org/10.1155/2014/657647 Influence of cooling rate on microsegregation behavior of magnesium alloys]", ''Journal of Materials'', Volume 2014 (2014), Article ID 657647, 18 pages. [http://downloads.hindawi.com/journals/jma/2014/657647.pdf (PDF version)] | ||

| + | |||

| + | [1] A. Mostafa, A. E. Gheribi, M. Mezbahul-Islam, D. Kevrokov, and M. Medraj, [http://dx.doi.org/10.1016/j.calphad.2013.07.004 Experimental Investigation and First-Principle Calculations Coupled with Thermodynamic Modeling of the Mn-Nd Phase Diagram], ''Calphad'', 42 (2013) 27-37. [https://www.mendeley.com/stats/articles/2-s2.0-84881534566 (<font color="green"><u>''Article Statistics''</u></font>)] | ||

'''''Refereed Conferences:''''' | '''''Refereed Conferences:''''' | ||

| − | [2] A. Mostafa, D. Kevorkov, A. Gheribi, M. Medraj, [[:File: | + | [8] Ahmad Mostafa, Ubeidallah Al-Qawabeh, Audai Al-Akailah, [https://drive.google.com/open?id=13u_jIOZwqljnc4TYWS14BzbBJ7FaYqp3 "Grain refinement of cast Zamak 5 alloy by 0.1, 0.2 and 0.5 wt.% Mn"], The Second International Conference on Engineering |

| + | and Science, March 28-30/2019, Antalya, Turkey. | ||

| + | |||

| + | [7] Ahmad Mostafa, Mohamed Shahtout, Tariq Al Afeefi and Mamoun Medraj, "Conversion of Electric Arc Furnace Dust into Ceramics Using Thermodynamic Calculations and Experimental Work", The 8th International Conference on Advanced Materials Research (ICAMR2018), January 20-22/2018, Fukuoka, Japan. | ||

| + | |||

| + | [6] Ahmad O. Mostafa, Mamoun Medraj, [https://dc725.4shared.com/img/q9frmS7Nei/s23/15f40844090/New_Doc_2017-10-20_1 "Determination of ternary phase diagrams using diffusion couples with key alloys approach"], The 1st international Conference on Mechanical Engineering Sciences and Applications MESA2017, Tafila Technical University, 8-10/10/2017. | ||

| + | |||

| + | [5] Adnan I. O. Zaid, Ahmad O. Mostafa, “Effect of Hafnium Addition to Zinc Aluminum Alloy 5, ZA5, on its Resistance to Wear: A Three-Dimensional Approach”, European Advanced Materials Congress, Stockholm, Sweden, August 2017. | ||

| + | |||

| + | [4] Shaheen Fatima Anis, Boor Singh Lalia, Ahmad O. Mostafa, Raid Hashaikeh, “Electrospun WO3-NiWO4 Composite Nano Fibers as Active Electrocatalysts for Hydrogen Evolution Reaction”, UAEGSRC'17, Al-Ain, UAE, April 2017. | ||

| + | |||

| + | [3] Ignacio Picazo Rubio, Ahmad O. Mostafa, Vladimir Brailovski, Mohammad Jahazi, Mamoun Medraj, “Evaluation of microstructure and mechanical behavior of 3D printed Inconel 718 alloy”, in: Aerospace Engineering, UAEGRSC 16th, Al-Ain, UAE, April 2016. | ||

| + | |||

| + | [2] A. Mostafa, D. Kevorkov, A. Gheribi, M. Medraj, [[:File:The Mg-Mn-Nd System Mg2012.pdf|The Mg-Mn-Nd System: Experimental Investigation Coupled with Thermodynamic Modeling]], ICMAA2012, 245-250. | ||

[1] A.I.O Zaid and A.O. Mostafa, [http://users.encs.concordia.ca/~tmg/images/2/2c/Dradnan_mostafa.pdf Effect of Addition of Hafnium (Hf) on the Mechanical Behavior and Wear Resistance of Zinc-Aluminum Alloy 5 (ZA5)], ICPR 21st, May, 2011, Stuttgart, Germany. | [1] A.I.O Zaid and A.O. Mostafa, [http://users.encs.concordia.ca/~tmg/images/2/2c/Dradnan_mostafa.pdf Effect of Addition of Hafnium (Hf) on the Mechanical Behavior and Wear Resistance of Zinc-Aluminum Alloy 5 (ZA5)], ICPR 21st, May, 2011, Stuttgart, Germany. | ||

| − | + | '''''Symposium Records:''''' | |

| − | + | [14] Ahmad O. Mostafa, " Advanced Manufacturing Processes Workshop”, Joran Engineers Association, Aqaba, Jordan, February 5th, 2024, Oral Presentation | |

| − | [ | + | [13] Ahmad O. Mostafa, "ECO-CAR Staff training at TTU from Budapest University of Management and Engineering (BME) TOT: ZalaZONE", Training of Trainers (TOT) at Tafila Technical University, November 2nd, 2022, ''Oral Presentation''. |

| − | [ | + | [12] Ahmad O. Mostafa, Mamoun Medraj, “Electrical arc furnace dust management in Emirates Steel Industries”, World future energy summit, Abu Dhabi, January 16-19, 2017, ''Oral presentation''. |

| − | [ | + | [11] Mamoun Medraj, Ahmad Mostafa, Dmytro Kevorkov, Tian Wang, “Materials Development for Improved Energy Efficiency and Reduced Environmental Impact”, in: Energy and Water in the Gulf Cooperation Council Countries: Present and Future Trends workshop the American University of Ras Al Khaimah, April 12-14, 2016. |

| − | [4] A. Mostafa, H. Alshahrani, K. Younes, S. Abdelkhalek, D. Ma, J. Ajaja, A. Karimi, and Y. Elshami, [http://users.encs.concordia.ca/~tmg/images/d/d9/ECSGA_Poster.pdf Design and Manufacturing of a Composites Seat], ECSGA Graduate Studend Poster Competition, Concordia University, Montreal, October, 2012. ''Poster presentation''. | + | [10] Mamoun Medraj, Ahmad Mostafa, Dmytro Kevorkov, Yinan Zhang, Md. Imran Khan, Md. Mezbahul Islam, “Understanding Equilibrium Phase Relations through Electron Microscopy”, Abu Dhabi, November 2-3, 2015. |

| + | |||

| + | [9] Ahmad Mostafa, “Experimental investigation of the Mg-Ce-Zn ternary phase diagram and diffusivity measurements of its constituent binary systems”, ''invited speaker'' in the PhD seminar course at MIST, Abu Dhabi, October 2015. | ||

| + | |||

| + | [8] Ahmad Mostafa and Mamoun Medraj, [http://users.encs.concordia.ca/~tmg/images/c/c2/Publication1.pdf Experimental investigation of the Ce-Mg-Mn isothermal section at 450°C via diffusion couples and key alloys techniques], MIE PhD Seminar Completion, Concordia University, Montreal, April 2014. ''Poster presentation'' | ||

| + | |||

| + | [7] Ahmad Mostafa and Mamoun Medraj, [[:File:MagNET AGM 2013 Ahmad Mostafa.pptx|Experimental investigation of the Mg-{Mn,Zn}-{Ce-Nd} ternary phase diagrams]], MagNET AGM, University of British Colombia, Vancouver, June 2013.''Oral presentation''. | ||

| + | |||

| + | [6] Ahmad Mostafa and Mamoun Medraj, [http://users.encs.concordia.ca/~tmg/images/5/50/ASM_student_night_feb.pdf Assessment of atomic interdiffusion of Mg and Nd in the Mg-Nd binary system], American Society of Metals (ASM) symposium, Montreal, February, 2013.''Poster presentation''. | ||

| + | |||

| + | [5] Ahmad Mostafa and Mamoun Medraj, [http://users.encs.concordia.ca/~tmg/images/0/0d/MagNET_3.pdf Assessment of Atomic Interdiffusion of the Mg-Mn-Nd Ternary System and its Constituent Binaries], MagNET workshop IX, McGill University, Montreal, November, 2012. ''Poster Presentation''. | ||

| + | |||

| + | [4] A. Mostafa, H. Alshahrani, K. Younes, S. Abdelkhalek, D. Ma, J. Ajaja, A. Karimi, and Y. Elshami, [http://users.encs.concordia.ca/~tmg/images/d/d9/ECSGA_Poster.pdf Design and Manufacturing of a Composites Seat], ECSGA Graduate Studend Poster Competition, Concordia University, Montreal, October, 2012. ''Poster presentation''. | ||

[3] A. Mostafa, A. E. Gheribi, D. Kevorkov, and M. Medraj, [http://users.encs.concordia.ca/~tmg/images/7/7f/MagNET_2.pdf Isothermal Section of the Mg-Mn-Nd system at 450C: Experimental Investigation and Thermodynamic Modeling], MagNET AGM, Waterloo, June, 2012.''Poster Presentation''. | [3] A. Mostafa, A. E. Gheribi, D. Kevorkov, and M. Medraj, [http://users.encs.concordia.ca/~tmg/images/7/7f/MagNET_2.pdf Isothermal Section of the Mg-Mn-Nd system at 450C: Experimental Investigation and Thermodynamic Modeling], MagNET AGM, Waterloo, June, 2012.''Poster Presentation''. | ||

| Line 90: | Line 277: | ||

[1] A. Mostafa, P. Ghosh, A. Pelton, and M. Medraj, [http://users.encs.concordia.ca/~tmg/images/5/5e/MagNET_poster.pub Experimental Investigation and Thermodynamic Modeling of Mg-{Mn, Zn}-{Ce, Nd} Ternary systems], MagNET AGM, Vancouver, June, 2011. | [1] A. Mostafa, P. Ghosh, A. Pelton, and M. Medraj, [http://users.encs.concordia.ca/~tmg/images/5/5e/MagNET_poster.pub Experimental Investigation and Thermodynamic Modeling of Mg-{Mn, Zn}-{Ce, Nd} Ternary systems], MagNET AGM, Vancouver, June, 2011. | ||

| − | == Awards == | + | == Honors and Awards == |

| − | *Nominated, by the School of Graduate Studies of Concordia University, for Graduate Certificate in University Teaching (UNIT) based on the excellent academic achievements (August, 2013) | + | *Graduation projects award for Jordan Universities, 2nd place, Jordan Engineers Association, Amman Chamber of Industry, Jordan, 2020 |

| + | *Formula Student UK, 2nd place design award, IMECH, Silverstone circuit, UK, 2018 | ||

| + | *Certified PTC Creo Parametric Educator, by Mechanical Engineering Department, Tafila Technical University, 2018 | ||

| + | *Nominated for the Governor General's Gold Medal Award 2015, by Mechanical and Industrial Engineering Department at Concordia University. | ||

| + | *[http://users.encs.concordia.ca/~tmg/images/1/16/GK-100.tif Golden Key International Honour Society], Concordia University, Canada, September 2014. | ||

| + | *Nominated for the Governor General's Gold Medal Award 2014, by Mechanical and Industrial Engineering Department at Concordia University. | ||

| + | *Concordia Accelerator Award, Concordia University, April 2014. | ||

| + | *[http://users.encs.concordia.ca/~tmg/images/e/e6/Seminar_award.PDF PhD Seminar Award] by Mechanical and Industrial Engineering Department at Concordia University, March 2014. | ||

| + | *Nominated, by the School of Graduate Studies of Concordia University, for Graduate Certificate in University Teaching (UNIT) based on the excellent academic achievements (August, 2013) | ||

*Concordia University Partial Tuition Scholarship for International Students (May 1, 2013 to April 30, 2014). | *Concordia University Partial Tuition Scholarship for International Students (May 1, 2013 to April 30, 2014). | ||

*Concordia University Partial Tuition Scholarship for International Students (September 1, 2012 to August 31, 2013). | *Concordia University Partial Tuition Scholarship for International Students (September 1, 2012 to August 31, 2013). | ||

*[http://www.magnet.ubc.ca/wiki/index.php/AGM_2012 Best Poster Presentation Award], MagNET AGM, University of Waterloo, June, 2012. | *[http://www.magnet.ubc.ca/wiki/index.php/AGM_2012 Best Poster Presentation Award], MagNET AGM, University of Waterloo, June, 2012. | ||

*Concordia University Partial Tuition Scholarship for International Students (September 1, 2011 to August 31, 2012). | *Concordia University Partial Tuition Scholarship for International Students (September 1, 2011 to August 31, 2012). | ||

| + | *University of Jordan. Excellent research student grant (2009), Amman, Jordan. | ||

*Ministry of Higher Education. Excellent student award (2004), Baghdad, Iraq. | *Ministry of Higher Education. Excellent student award (2004), Baghdad, Iraq. | ||

== Teaching Experience == | == Teaching Experience == | ||

| − | ''' | + | '''4- From September 2017 to Present |

| − | <u> | + | <u>Teaching the following courses at Tafila Technical University, Department of Mechanical Engineering</u>''<u>,</u>'' |

| + | * Metrology Science | ||

| + | * Metal Forming | ||

| + | * CAD/CAM | ||

| + | * Mechanical Drawing using Creo Parametric | ||

| + | <br> | ||

| + | '''3- From 2015 to 2017''' | ||

| − | '' | + | <u>Working for Masdar Institute, Department of Mechanical and Materials Engineering</u>''<u>,</u>'' as: |

| + | * on-demand lecturer for MSE 521 (Properties and Failure of Materials) course. | ||

| + | * on-demand lecturer for MSE 507 (Thermodynamics of Materials) course. | ||

| + | <br> | ||

| − | + | '''2- From 2012-2014''' | |

| − | < | + | <u>Working for Concordia University, Department of Mechanical Engineering</u>''<u>,</u>'' as TA Leader and marker for: |

| + | * MECH 321 (Properties and Failure of Materials) course. | ||

| + | * MECH 221 (Materials Science) course. | ||

| − | + | <br> | |

| − | + | ||

| − | <br> | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | '''1- From 2009 to 2010''' | |

| − | <u>Working for University of Jordan | + | <u>Working for University of Jordan, Faculty of Engineering and Technology, Department of Industrial Engineering</u> as an assistant teacher in the manufacturing processes laboratory. The taught topics involved: metal casting, wear of metals, mechanical behavior, rolling of metals, deep drawing, blanking and piercing of sheet metals, and extrusion of metals. |

| − | == | + | == Industrial Experience == |

'''1- From 1/8/2009 to 12/01/2011: ''' | '''1- From 1/8/2009 to 12/01/2011: ''' | ||

| − | <u>Working for Qaraman Co. for Bolts and Spare Parts Ltd. as: </u> | + | <u>Working for [http://qaramangroup.com/#page_1/ Qaraman Co. for Bolts and Spare Parts Ltd.] as: </u> |

Manager of steel heat treatment department. | Manager of steel heat treatment department. | ||

| Line 137: | Line 336: | ||

'''2- From 1/9/2007 to 1/7/2009: ''' | '''2- From 1/9/2007 to 1/7/2009: ''' | ||

| − | <u>Working for | + | <u>Working for Al-Balqa for Metals and Tools Co. as: </u> |

''i. Technical Manager with the following duties. '' | ''i. Technical Manager with the following duties. '' | ||

| Line 165: | Line 364: | ||

''iv. Preparing daily reports explaining melting and heat-treatment procedures.'' | ''iv. Preparing daily reports explaining melting and heat-treatment procedures.'' | ||

| − | [[Category: | + | [[Category:Alumni]] |

Latest revision as of 19:14, 27 July 2024

| Full name | Ahmad Omar Mostafa |

| a_mostaf[at]live.concordia.ca | |

| Room # | {{{office}}} |

Dr. Mostafa is currently an Associate Professor in the Mechanical Engineering Department at Tafila Technical University, Jordan. His PhD degree was obtained from Concordia University in Mechanical Engineering and focused on Materials Science. He published novel papers in materials science field, expert in alloy design and development, modeling and experimental investigation of metallic phase diagrams, advanced tooling design and manufacturing, and a verified reviewer for prestigious journals. Dr. Mostafa has an extensive research collaboration, teaching and mentoring experience, extracurricular activities, and 5 years engineering experience in steel industry.

Contents |

Education

- 2015-2017:

Postdoctorl Researcher, Mechanical and Materials Engineering Department, Masdar Institute of Science and Technology, Abu Dhabi, UAE.

- 2014-2015:

Postdoctorl Fellowship, Mechanical Engineering Department, Concordia University, Montreal, Canada.

- 2011-2014:

PhD Degree in Mechanical Engineering, under the supervision of Prof. Mamoun Medraj, Concordia University, Montreal, Canada.

- 2006 - 2009:

Masters Degree in Industrial engineering/Manufacturing and design under the supervision of Prof. Adnan Alkilani, Jordan University, Amman, Jordan.

- 2000 - 2004:

Bachelore Degree in Materials Engineering Technique, Middle Technical University, Baghdad, Republic of Iraq.

Research Fields

- Additive manufacturing of IN718 superalloys

- Development of magnetic materials

- Alloys grain refinement

- Water erosion failure analysis

- Metal forming die design (Deep drawing and asymmetric angle extrusion dies)

- Atomic interdiffusion measurements of binary and ternary systems

- Phase diagram investigation using computational thermodynamics coupled with key experiments as shown below:

- Polymer matrix composite materials:

Research Qualifications

- Expert in operating HITACHI-S3400 SEM equipped with EDS/WDS detectors.

- Verified Peer Reviewer:

- Scientific Reports

- International Journal of Materials Research (formerly: Zeitschrift fuer Metallkunde)

- Journal of Materials and Design (JMAD)

- Science and Engineering of Composites Materials

- Expert in phase diagram investigation using:

- ICP

- DSC

- XRD

- XRF

- TEM

- FIB

- SEM, EBSD, EDS and WDS

- Quartz tube sealing

- Induction and arc melting furnaces

- Atomic/Magnetic Force Microscopy (AFM/MFM)

- Very familiar with metal machining and cutting equipment, such as:

- Lathe machines (Concordia University approval)

- Milling machines (Concordia University approval)

- Shaping machines

- Water-jet cutting machine

- Passed Concordia University radiation safety exam

- Passed Concordia University corrosive materials safety training

- Passed Concordia University EDML safety exam

- Excellent cooperative with all group members from different topics

Research Work

- Associate Professor, September 2022- Present

Affiliation: Mechanical Engineering Department at Tafila Technical University

Projects: - Effect of grain refiners on the mechanical properties of Al and Zn alloys

- Phase diagrams

- Additive manufacturing

- Electric arc furnace dust (EAFD) Analysis

- Assistant Professor, September 2017 - September 2022

Affiliation: Mechanical Engineering Department at Tafila Technical University

Projects: - Effect of grain refiners on the mechanical properties of Al and Zn alloys

- Phase diagrams

- Additive manufacturing

- Electric arc furnace dust (EAFD) Analysis

- Postdoctoral Researcher, May 2015 - August 2017

Affiliation: Mechanical and Materials Engineering Department at Masdar Institute of Science and Technology

Projects: - Development of Magnetic Materials

- Phase diagrams of solar cell materials

- Additive manufacturing of SLM 3D printed IN718 superalloy

- Electric arc furnace dust (EAFD) management

- Postdoctoral fellow, August 2014 - May 2015

Affiliation: Mechanical and Industrial Engineering Department at Concordia University.

Tasks: - Performing experimental and theoretical experiments on different phase diagrams

- Training and guiding the students in the thermodynamics of materials group (TMG)

- Reviewing students theses and publications

- PhD Thesis, January 2011 - May 2014

Affiliation: Mechanical and Industrial Engineering Department at Concordia University.

Thesis title: Experimental Investigation of the Phase Equilibria in the Mg-Mn-{Ce, Nd} and Ce-Mg-Zn Ternary Systems and Diffusivity Measurements of the Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} Binary Systems

Summary: In this work, the 450°C Mg-Mn-{Ce, Nd} and 300°C Ce-Mg-Zn isothermal sections were established using diffusion couples and key alloys. The phase relationships were determined using XDR, EDS/WDS and metallography. Diffusion couples were also used to measure the interdiffusion coefficients of the Mg-{Ce, Nd, Zn} and Zn-{Ce, Nd} binary systems based on the experimental composition profiles and Boltzmann-Matano method.

- MSc Thesis, September 2006 - September 2009

Affiliation: Industrial Engineering/Design and Manufacturing Department at Jordan University.

Thesis title: Effect of addition of Hf on the Mechanical Behavior and Wear Resistance of ZA5 Alloy

Summary: The ZA5 alloy melt solidifies with dendritic structure of large grain size, which affects its mechanical behavior and surface quality. This alloy is normally grain refined by some refiners like Titanium or Titanium+Boron additives. In this work, the effect of addition of hafnium (Hf) at different weight percentages, ranging from 0.02% to 0.12%, to ZA5 as a grain refiner on its micro structure, hardness, mechanical behavior and wear resistant, was investigated.

Published Works

Find me on: Scopus, Orcid, Google Scholar, LinkedIn, Research Gate, WOS, YouTube, KUDOS, Semantic Scholar

Journal Publications

[35] Mostafa, Ahmad Omar. "Navigating Joining Challenges in Friction Stir Welding of Hybrid Composite Structures ." Utilizing Friction Stir Techniques for Composite Hybridization. IGI Global, 2024. 382-406. DOI: 10.4018/979-8-3693-3993-0.ch018

[34] KY Eayal Awwad, Khosro Fallahnezhad, BF Yousif, Ahmad Mostafa, Omar Alajarmeh, A Shalwan, Xuesen Zeng, "Finite element analysis and experimental validation of polymer–metal contacts in block-on-ring configuration", Friction, 2024, 12, 3, pp. 554-568. doi: 10.1007/s40544-023-0795-x.

[33] Hanan Saleet , Alaa Aldamsah, Mohamad Banikhaled, Ayman Abu-Baker, Rebhi A. Damseh, Ma’moun Al-Smadi, Ahmad Mostafa, Wael Adaileh, Ali Alahmer, Ahmed Al-Salaymeh, Sara Al Twassi, Rasha AlBeek and Kholoud Hassouneh, "Importance and Barriers of Establishing Educational/Training Programs in Electric Vehicles/Hybrid-Electric Vehicles in Jordan", World Electric Vehicle Journal, 2023, 14(9), 232. doi:10.3390/wevj14090232

[32] W Adaileh, R Alhdayat, A Mostafa, "Selection of material and process for a brake pad using CES software", Utilitas Mathematica 120, 356-367.

[31] K. Y. Eayal Awwad, B. F. Yousif, Ahmad Mostafa, Omar Alajarmeh, and Xuesen Zeng, "Tribological and mechanical performances of newly developed eco-epoxy composites incorporating flax fibres and graphene nanoplatelets", Journal of Reinforced Plastics and Composites, 2023;42(17-18):939-952. doi:10.1177/07316844221143451

[30] Ahmad Mostafa and Nabeel Alshabatat, "Microstructural, Mechanical and Wear Properties of Al–1.3%Si Alloy as Compared to Hypo/ Hyper–Eutectic Compositions in Al–Si Alloy System", Crystals 2022, 12(5), 719; https://doi.org/10.3390/cryst12050719.

[29] Alahmer, A.; Rezk, H.; Aladayleh, W.; Mostafa, A.O.; Abu-Zaid, M.; Alahmer, H.; Gomaa, M.R.; Alhussan, A.A.; Ghoniem, R.M. Modeling and Optimization of a Compression "Ignition Engine Fueled with Biodiesel Blends for Performance Improvement", Mathematics 2022, 10(3), 420; https://doi.org/10.3390/math10030420.

[28] M. Sadeghi Gogheri, M. Kasiri-Asgarani, H. Reza Bakhsheshi-Rad, H. Ghayour, M. Rafiei, A. Mostafa, F. Berto, "Friction welding of pure titanium-AZ31 magnesium alloy: Characterization and simulation", Eng. Fail. Anal. (2022) 105799. doi:10.1016/j.engfailanal.2021.105799.

[27] Alahmer, A.; Al-Amayreh, M.; Mostafa, A.O.; Al-Dabbas, M.; Rezk, H. "Magnetic Refrigeration Design Technologies: State of the Art and General Perspectives". Energies 2021, 14, 4662. DOI:10.3390/en14154662

[26] A. Mostafa, W. Adaileh, A. Awad, A. Kilani, "Mechanical Properties of Commercial Purity Aluminum Modified by Zirconium Micro‐Additives". Crystals 2021, 11, 270. DOI:10.3390/cryst11030270

[25] S. Al-Qawabah, A. Mostafa, A. Al-Rawajfeh, U. Al-Qawabeha, "Effect of Heat Treatment on the Grain Size, Microhardness and Corrosion Behavior of the Cold-Working Tool Steels AISI D2 and AISI O1", MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY, 2020, Vol. 54, issue 6, pp 785–790. DOI:10.17222/mit.2020.035

[24] L. Hai Tat, H. R. Bakhsheshi-Rad, E. Hamzah, M.H. Cho, A. Mostafa, S. Farahany, "Microstructure, phase evolution and corrosion behavior of the Zn-Al-Mg-Sb coated alloys", Materials Science and Technology, 2020, vol 36, issue 3, pp 353-366. DOI:10.1080/02670836.2019.1705587.

[23] Shaheen Anis, Ahmad Mostafa, Nidal Hilal, Raed Hashaikeh, "Nanocrystalline NiWO4-WO3-WO2.9 Composite strings: Fabrication, Characterization and their Electrocatalytic Performance for Hydrogen Evolution Reaction", Metallurgical and Materials Transactions A, 2020, vol 51, issue 3, pp 1264–1274. DOI:10.1007/s11661-019-05596-0.

[22] Ahmad Mostafa, Ubeidallah Al-Qawabeh, Audai Al-Akailah, "Grain refinement of cast Zamak 5 alloy by 0.1, 0.2 and 0.5 wt.% Mn", Al-Hussein Bin Talal's University Journal of Research, 2019, Vol 1, Issue 1, pp 1-15.

[21] Ahmad Mostafa, "Mechanical Properties and Wear Behavior of Aluminum Grain Refined by Ti and Ti+B ", International Journal of Surface Engineering and Interdisciplinary Materials Science, 2019, 7(1), pp 1-19. DOI:10.4018/IJSEIMS.2019010101

[20] Raiyan Seede, Ahmad Mostafa, Vladimir Brailovski, Mohammad Jahazi and Mamoun Medraj, “Microstructural and Microhardness Evolution from Homogenization and Hot Isostatic Pressing on Selective Laser Melted Inconel 718: Structure, Texture, and Phases”, Manufacturing and Materials Processing, 2018, 2, 30. DOI:10.3390/jmmp2020030

[19] Ahmad Mostafa, Mohamed Shahtout, Tariq Al Afeefi and Mamoun Medraj, "Conversion of Electric Arc Furnace Dust into Ceramics Using Thermodynamic Calculations and Experimental Work", Key Engineering Materials (ISSN: 1662-9795), 2018, 765, pp 73-78. DOI:10.4028/www.scientific.net/KEM.765.73

[18] Ahmad Mostafa, Davood Shahriari, Ignacio Picazo Rubio, Vladimir Brailovski, Mohammad Jahazi and Mamoun Medraj, "Hot compression behavior andmicrostructure of selectively laser-melted IN718 alloy", The International Journal of Advanced Manufacturing Technology, 2018, 96, 371. DOI:10.1007/s00170-017-1522-4

[17] Ahmad Mostafa، Mamoun Medraj, "Binary phase diagrams and thermodynamic properties of silicon and essential doping elements (Al, As, B, Bi, Ga, In, N, P, Sb and Tl)", Materials, 2017, 10(6), 676. DOI:10.3390/ma10060676

[16] Ahmad Mostafa , Ignacio Picazo Rubio , Vladimir Brailovski , Mohammad Jahazi , Mamoun Medraj, "Structure, texture and phases in 3D printed IN718 alloy subjected to homogenization and HIP treatments", Metals, 2017, 7(6), 196. DOI:10.3390/met7060196

[15] Bolarinwa Komolafe, Ahmad Mostafa, "Wetting and spreading behaviour of Ti-based brazing filler on Ti64 substrate", Materials Research Express, 2017, 6(4), 066503. DOI:10.1088/2053-1591/aa7311

[14] Adnan I. O. Zaid, Ahmad Mostafa, "Effect of Hafnium Addition on Wear Resistance of Zinc-Aluminum 5 Alloy: a Three-Dimensional Presentation", Advanced Materials Letters, 2017, Vol 8, Issue 9, pp 910-915. DOI:10.5185/amlett.2017.1662

[13] Shaheen F Anis, Boor S Lalia, Ahmad O Mostafa, Raed Hashaikeh, “Electrospun Nickel-Tungsten Oxide Composite Fibers as Active Electrocatalysts for Hydrogen Evolution Reaction”, Journal of Materials Science', 52(12):7269–7281. DOI:10.1007/s10853-017-0964-2

[12] H.R. Bakhsheshi-Rada, E. Hamzah, S.L. Joy Yii, A. Mostafa, R. Ebrahimi-Kahrizsangi, M. Medraj, “Characterization and thermodynamic calculations of biodegradable Mg-2.2Zn-3.7Ce and Mg-Ca-2.2Zn-3.7Ce alloys”, Materials Science and Technology, 2017, 33(11), pp 1333-1345. DOI: 10.1080/02670836.2017.1288777

[11] H. Bakhsheshi, E. Hamzah, H. Low, M. Cho, M. Kasiri, S. Farahany, A. Mostafa, M. Medraj, “Thermal characteristics, mechanical properties, in-vitro degradation and cytotoxicity of novel biodegradable Zn-Al-Mg and Zn-Al-Mg-xBi alloys”, Acta Metallurgica Sinica (English letters), Volume 30, Issue 3, pp 201–211. DOI: 10.1007/s40195-017-0534-2

[10] Dina Ma, Ahmad Mostafa, Dmytro Kevorkov, Pawel Jedrzejowski, Martin Pugh, Mamoun Medraj, "Water impingement erosion of deep rolled Ti64", Metals 2015, 5 (3), 1462-1486; doi:10.3390/met5031462. (Article Statistics)

[9] Ahmad Mostafa and Mamoun Medraj, "Experimental investigation of the Mg-Nd-Zn isothermal section at 300 ºC", Metals 2015, 5(1), 84-101; doi:10.3390/met5010084 (Article Statistics)

[8] T. Wang, D. Kevorkov, A. Mostafa, and M. Medraj, "Experimental investigation of the phase equilibria in the Al-Mn-Zn system at 400°C", Journal of Materials, vol. 2014, Article ID 451587, 13 pages, 2014. doi:10.1155/2014/451587

[7] A. Mostafa and M. Medraj, "On the atomic interdiffusion in Mg-{Ce,Nd,Zn} and Zn-{Ce,Nd} binary systems", Journal of Materials Research, 29(13), (2014) 1463-1479. (Article Statistics)

[6] Ahmad Mostafa, and Mamoun Medraj, "Phase Equilibria of the Ce-Mg-Zn Ternary System at 300 °C", Metals 2014, 4(2), 168-195; doi:10.3390/met4020168. (PDF version). (Article Statistics)

[5] Ahmad Mostafa, and Mamoun Medraj, "Experimental investigation of the Mg-Mn-Nd isothermal section at 450°C", Journal of Alloys and Compounds, 608 (2014) 247-257.

[4] Ahmad Mostafa, and Mamoun Medraj, "Experimental investigation of the Ce-Mg-Mn isothermal section at 723K (450°C) via diffusion couples technique", Metallurgical and Materials Transactions A, 45 (2014) 3144-3160. (Article Statistics)

[3] Md. Mezbahul Islam, Ahmad Mostafa, and Mamoun Medraj, "Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical Data", Journal of materials, Volume 2014 (2014), Article ID 704283, 33 pages. (PDF version)

[2] Md. I. Khan, A. Mostafa, M. Aljarrah, E. Essadiqi and M. Medraj, "Influence of cooling rate on microsegregation behavior of magnesium alloys", Journal of Materials, Volume 2014 (2014), Article ID 657647, 18 pages. (PDF version)

[1] A. Mostafa, A. E. Gheribi, M. Mezbahul-Islam, D. Kevrokov, and M. Medraj, Experimental Investigation and First-Principle Calculations Coupled with Thermodynamic Modeling of the Mn-Nd Phase Diagram, Calphad, 42 (2013) 27-37. (Article Statistics)

Refereed Conferences:

[8] Ahmad Mostafa, Ubeidallah Al-Qawabeh, Audai Al-Akailah, "Grain refinement of cast Zamak 5 alloy by 0.1, 0.2 and 0.5 wt.% Mn", The Second International Conference on Engineering and Science, March 28-30/2019, Antalya, Turkey.

[7] Ahmad Mostafa, Mohamed Shahtout, Tariq Al Afeefi and Mamoun Medraj, "Conversion of Electric Arc Furnace Dust into Ceramics Using Thermodynamic Calculations and Experimental Work", The 8th International Conference on Advanced Materials Research (ICAMR2018), January 20-22/2018, Fukuoka, Japan.

[6] Ahmad O. Mostafa, Mamoun Medraj, "Determination of ternary phase diagrams using diffusion couples with key alloys approach", The 1st international Conference on Mechanical Engineering Sciences and Applications MESA2017, Tafila Technical University, 8-10/10/2017.

[5] Adnan I. O. Zaid, Ahmad O. Mostafa, “Effect of Hafnium Addition to Zinc Aluminum Alloy 5, ZA5, on its Resistance to Wear: A Three-Dimensional Approach”, European Advanced Materials Congress, Stockholm, Sweden, August 2017.

[4] Shaheen Fatima Anis, Boor Singh Lalia, Ahmad O. Mostafa, Raid Hashaikeh, “Electrospun WO3-NiWO4 Composite Nano Fibers as Active Electrocatalysts for Hydrogen Evolution Reaction”, UAEGSRC'17, Al-Ain, UAE, April 2017.

[3] Ignacio Picazo Rubio, Ahmad O. Mostafa, Vladimir Brailovski, Mohammad Jahazi, Mamoun Medraj, “Evaluation of microstructure and mechanical behavior of 3D printed Inconel 718 alloy”, in: Aerospace Engineering, UAEGRSC 16th, Al-Ain, UAE, April 2016.

[2] A. Mostafa, D. Kevorkov, A. Gheribi, M. Medraj, The Mg-Mn-Nd System: Experimental Investigation Coupled with Thermodynamic Modeling, ICMAA2012, 245-250.

[1] A.I.O Zaid and A.O. Mostafa, Effect of Addition of Hafnium (Hf) on the Mechanical Behavior and Wear Resistance of Zinc-Aluminum Alloy 5 (ZA5), ICPR 21st, May, 2011, Stuttgart, Germany.

Symposium Records:

[14] Ahmad O. Mostafa, " Advanced Manufacturing Processes Workshop”, Joran Engineers Association, Aqaba, Jordan, February 5th, 2024, Oral Presentation

[13] Ahmad O. Mostafa, "ECO-CAR Staff training at TTU from Budapest University of Management and Engineering (BME) TOT: ZalaZONE", Training of Trainers (TOT) at Tafila Technical University, November 2nd, 2022, Oral Presentation.

[12] Ahmad O. Mostafa, Mamoun Medraj, “Electrical arc furnace dust management in Emirates Steel Industries”, World future energy summit, Abu Dhabi, January 16-19, 2017, Oral presentation.

[11] Mamoun Medraj, Ahmad Mostafa, Dmytro Kevorkov, Tian Wang, “Materials Development for Improved Energy Efficiency and Reduced Environmental Impact”, in: Energy and Water in the Gulf Cooperation Council Countries: Present and Future Trends workshop the American University of Ras Al Khaimah, April 12-14, 2016.

[10] Mamoun Medraj, Ahmad Mostafa, Dmytro Kevorkov, Yinan Zhang, Md. Imran Khan, Md. Mezbahul Islam, “Understanding Equilibrium Phase Relations through Electron Microscopy”, Abu Dhabi, November 2-3, 2015.

[9] Ahmad Mostafa, “Experimental investigation of the Mg-Ce-Zn ternary phase diagram and diffusivity measurements of its constituent binary systems”, invited speaker in the PhD seminar course at MIST, Abu Dhabi, October 2015.

[8] Ahmad Mostafa and Mamoun Medraj, Experimental investigation of the Ce-Mg-Mn isothermal section at 450°C via diffusion couples and key alloys techniques, MIE PhD Seminar Completion, Concordia University, Montreal, April 2014. Poster presentation

[7] Ahmad Mostafa and Mamoun Medraj, Experimental investigation of the Mg-{Mn,Zn}-{Ce-Nd} ternary phase diagrams, MagNET AGM, University of British Colombia, Vancouver, June 2013.Oral presentation.

[6] Ahmad Mostafa and Mamoun Medraj, Assessment of atomic interdiffusion of Mg and Nd in the Mg-Nd binary system, American Society of Metals (ASM) symposium, Montreal, February, 2013.Poster presentation.

[5] Ahmad Mostafa and Mamoun Medraj, Assessment of Atomic Interdiffusion of the Mg-Mn-Nd Ternary System and its Constituent Binaries, MagNET workshop IX, McGill University, Montreal, November, 2012. Poster Presentation.

[4] A. Mostafa, H. Alshahrani, K. Younes, S. Abdelkhalek, D. Ma, J. Ajaja, A. Karimi, and Y. Elshami, Design and Manufacturing of a Composites Seat, ECSGA Graduate Studend Poster Competition, Concordia University, Montreal, October, 2012. Poster presentation.

[3] A. Mostafa, A. E. Gheribi, D. Kevorkov, and M. Medraj, Isothermal Section of the Mg-Mn-Nd system at 450C: Experimental Investigation and Thermodynamic Modeling, MagNET AGM, Waterloo, June, 2012.Poster Presentation.

[2] A. Mostafa, D. Kevorkov, and M. Medraj, Experimental Investigation of Mg-Mn-Nd Phase Diagram, American Society of Metals (ASM) symposium, Montreal, April, 2012.Poster presentation.

[1] A. Mostafa, P. Ghosh, A. Pelton, and M. Medraj, Experimental Investigation and Thermodynamic Modeling of Mg-{Mn, Zn}-{Ce, Nd} Ternary systems, MagNET AGM, Vancouver, June, 2011.

Honors and Awards

- Graduation projects award for Jordan Universities, 2nd place, Jordan Engineers Association, Amman Chamber of Industry, Jordan, 2020

- Formula Student UK, 2nd place design award, IMECH, Silverstone circuit, UK, 2018

- Certified PTC Creo Parametric Educator, by Mechanical Engineering Department, Tafila Technical University, 2018

- Nominated for the Governor General's Gold Medal Award 2015, by Mechanical and Industrial Engineering Department at Concordia University.

- Golden Key International Honour Society, Concordia University, Canada, September 2014.

- Nominated for the Governor General's Gold Medal Award 2014, by Mechanical and Industrial Engineering Department at Concordia University.

- Concordia Accelerator Award, Concordia University, April 2014.

- PhD Seminar Award by Mechanical and Industrial Engineering Department at Concordia University, March 2014.

- Nominated, by the School of Graduate Studies of Concordia University, for Graduate Certificate in University Teaching (UNIT) based on the excellent academic achievements (August, 2013)

- Concordia University Partial Tuition Scholarship for International Students (May 1, 2013 to April 30, 2014).

- Concordia University Partial Tuition Scholarship for International Students (September 1, 2012 to August 31, 2013).

- Best Poster Presentation Award, MagNET AGM, University of Waterloo, June, 2012.

- Concordia University Partial Tuition Scholarship for International Students (September 1, 2011 to August 31, 2012).

- University of Jordan. Excellent research student grant (2009), Amman, Jordan.

- Ministry of Higher Education. Excellent student award (2004), Baghdad, Iraq.

Teaching Experience

4- From September 2017 to Present

Teaching the following courses at Tafila Technical University, Department of Mechanical Engineering,

- Metrology Science

- Metal Forming

- CAD/CAM

- Mechanical Drawing using Creo Parametric

3- From 2015 to 2017

Working for Masdar Institute, Department of Mechanical and Materials Engineering, as:

- on-demand lecturer for MSE 521 (Properties and Failure of Materials) course.

- on-demand lecturer for MSE 507 (Thermodynamics of Materials) course.

2- From 2012-2014

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for:

- MECH 321 (Properties and Failure of Materials) course.

- MECH 221 (Materials Science) course.

1- From 2009 to 2010

Working for University of Jordan, Faculty of Engineering and Technology, Department of Industrial Engineering as an assistant teacher in the manufacturing processes laboratory. The taught topics involved: metal casting, wear of metals, mechanical behavior, rolling of metals, deep drawing, blanking and piercing of sheet metals, and extrusion of metals.

Industrial Experience

1- From 1/8/2009 to 12/01/2011:

Working for Qaraman Co. for Bolts and Spare Parts Ltd. as:

Manager of steel heat treatment department.

2- From 1/9/2007 to 1/7/2009:

Working for Al-Balqa for Metals and Tools Co. as:

i. Technical Manager with the following duties.

- Technical Support for BOHLER special steels (Steel selection & steel heat treatment).

- Marketing of BOHLER special steels.

3- From 1/7/2006 to 31/8/2007:

Working for Al-Hijaz Engineered Machining Establishment with its sister company (National Industrial Rehabilitation Company - NIRCO) as:

i. Marketing engineer of BELZONA products.

ii.Mechanical designer using AutoCAD.

4- From 20/11/2004 to 28/2/2006:

Working for SHEBA Metal Casting Company as:

i. Production engineer

ii. Heat treatment furnace operator.

iii. Patterns designe using AutoCAD software.

iv. Preparing daily reports explaining melting and heat-treatment procedures.