Ahmad Mostafa - Post Doc

Ahmadomar82 (Talk | contribs) (→Published Works) |

Ahmadomar82 (Talk | contribs) (→Work Experience) |

||

| Line 145: | Line 145: | ||

'''2- From 1/9/2007 to 1/7/2009: ''' | '''2- From 1/9/2007 to 1/7/2009: ''' | ||

| − | <u>Working for | + | <u>Working for Al-Balqa for Metals and Tools Co. as: </u> |

''i. Technical Manager with the following duties. '' | ''i. Technical Manager with the following duties. '' | ||

Revision as of 22:16, 30 April 2014

| Full name | Ahmad Omar Mostafa |

| ah_mosta[at]encs.concordia.ca | |

| Room # | EV13.161 |

I am materials engineer, I have a very good experience in metals manufacturing, fabrication, and heat treatment. Also, I have extensive knowledge in steel hardening on both scales (surface and through hardening) using several techniques, such as: electric resistance furnaces, salt bath furnaces, carburizing and carbonitriding, and flame hardening. Furthermore, I worked with Prof. Adnan I.O. Kilani as a research assistant for designing and manufacturing metal forming dies (deep drawing and asymmetric-angle extrusion dies). To fulfill my ambition, I decided to complete my Ph.D study in Concordia University under the supervision of Prof. Mamoun Medraj as a step of coupling my practical experience with the academic part.

Contents |

Education

- January, 2011 - present:

PhD candidate at Concordia University/Faculty of Mechanical Engineering, under the supervision of Prof. Mamoun Medraj, Montreal, Canada.

- 2006 - 2009:

Masters Degree in Industrial engineering/Manufacturing and design under the supervision of Prof. Adnan Alkilani, from Jordan University, Amman, Jordan.

- 2000 - 2004:

Bachelore Degree in Materials Engineering Techniques from Technical College, Baghdad, Republic of Iraq.

Research Fields

- Alloys grain refinement

- Metal forming die design (Deep drawing and asymmetric angle extrusion dies)

- Atomic interdiffusion measurements of binary and ternary systems

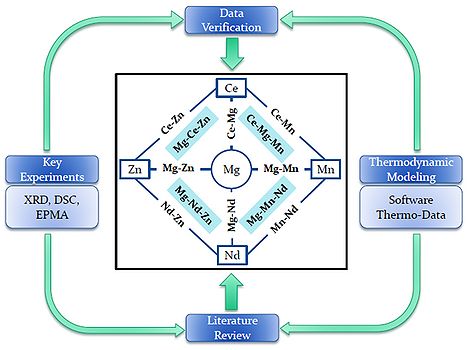

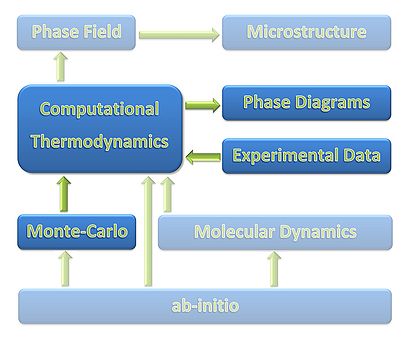

- Investigation of phase diagrams through computational thermodynamics coupled with key experiments as shown below:

Research Qualifications

- Capable to operate the HITACHI-S3400 SEM equipped with EDS/WDS detectors.

- A reviewer for the Science and Engineering of Composites Materials Journal

- Very familiar with phase diagram investigation equipments, such as:

- ICP

- DSC

- XRD

- SEM, EDS and WDS

- Quartz tube sealing

- Induction and arc melting furnaces

- Atomic/Magnetic Force Microscopy (AFM/MFM)

- Very familiar with metal machining and cutting equipment, such as:

- Lathe machines (Concordia University approval)

- Milling machines (Concordia University approval)

- Shaping machines

- Water-jet cutting machine

- Passed Concordia University radiation safety exam

- Passed Concordia University corrosive materials safety training

- Passed Concordia University EDML safety exam

- Excellent cooperative with all group members from different topics

Published Works

Journal Publications

[5] Ahmad Mostafa, and Mamoun Medraj, "Experimental investigation of the Mg-Mn-Nd isothermal section at 450°C", Journal of Alloys and Compounds, (in press).

[4] Ahmad Mostafa, and Mamoun Medraj, "Experimental investigation of the Ce-Mg-Mn isothermal section at 723K (450°C) via diffusion couples technique", Metallurgical and Materials Transactions A, 45 (2014) 3144-3160.

[3] Md. Mezbahul Islam, Ahmad Mostafa, and Mamoun Medraj, "Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical Data", Journal of materials, Volume 2014 (2014), Article ID 704283, 33 pages. (PDF version)

[2] Md. I. Khan, A. Mostafa, M. Aljarrah, E. Essadiqi and M. Medraj, "Influence of cooling rate on microsegregation behavior of magnesium alloys", Journal of Materials, Volume 2014 (2014), Article ID 657647, 18 pages. (PDF version)

[1] A. Mostafa, A. E. Gheribi, M. Mezbahul-Islam, D. Kevrokov, and M. Medraj, Experimental Investigation and First-Principle Calculations Coupled with Thermodynamic Modeling of the Mn-Nd Phase Diagram, Calphad, 42 (2013) 27-37. (Article Statistics)

Refereed Conferences:

[2] A. Mostafa, D. Kevorkov, A. Gheribi, M. Medraj, The Mg-Mn-Nd System: Experimental Investigation Coupled with Thermodynamic Modeling, ICMAA2012, 245-250.

[1] A.I.O Zaid and A.O. Mostafa, Effect of Addition of Hafnium (Hf) on the Mechanical Behavior and Wear Resistance of Zinc-Aluminum Alloy 5 (ZA5), ICPR 21st, May, 2011, Stuttgart, Germany.

Symposium Records:

[8] Ahmad Mostafa and Mamoun Medraj, Experimental investigation of the Ce-Mg-Mn isothermal section at 450°C via diffusion couples and key alloys techniques, MIE PhD Seminar Completion, Concordia University, Montreal, April 2014. Poster presentation

[7] Ahmad Mostafa and Mamoun Medraj, Experimental investigation of the Mg-{Mn,Zn}-{Ce-Nd} ternary phase diagrams, MagNET AGM, University of British Colombia, Vancouver, June 2013.Oral presentation.

[6] Ahmad Mostafa and Mamoun Medraj, Assessment of atomic interdiffusion of Mg and Nd in the Mg-Nd binary system, American Society of Metals (ASM) symposium, Montreal, February, 2013.Poster presentation.

[5] Ahmad Mostafa and Mamoun Medraj, Assessment of Atomic Interdiffusion of the Mg-Mn-Nd Ternary System and its Constituent Binaries, MagNET workshop IX, McGill University, Montreal, November, 2012. Poster Presentation.

[4] A. Mostafa, H. Alshahrani, K. Younes, S. Abdelkhalek, D. Ma, J. Ajaja, A. Karimi, and Y. Elshami, Design and Manufacturing of a Composites Seat, ECSGA Graduate Studend Poster Competition, Concordia University, Montreal, October, 2012. Poster presentation.

[3] A. Mostafa, A. E. Gheribi, D. Kevorkov, and M. Medraj, Isothermal Section of the Mg-Mn-Nd system at 450C: Experimental Investigation and Thermodynamic Modeling, MagNET AGM, Waterloo, June, 2012.Poster Presentation.

[2] A. Mostafa, D. Kevorkov, and M. Medraj, Experimental Investigation of Mg-Mn-Nd Phase Diagram, American Society of Metals (ASM) symposium, Montreal, April, 2012.Poster presentation.

[1] A. Mostafa, P. Ghosh, A. Pelton, and M. Medraj, Experimental Investigation and Thermodynamic Modeling of Mg-{Mn, Zn}-{Ce, Nd} Ternary systems, MagNET AGM, Vancouver, June, 2011.

Awards

- Concordia Accelerator Award, Concordia University, April 2014.

- PhD Seminar Award by the Mechanical and Industrial Engineering Department at Concordia University, March 2014.

- Nominated, by the School of Graduate Studies of Concordia University, for Graduate Certificate in University Teaching (UNIT) based on the excellent academic achievements (August, 2013)

- Concordia University Partial Tuition Scholarship for International Students (May 1, 2013 to April 30, 2014).

- Concordia University Partial Tuition Scholarship for International Students (September 1, 2012 to August 31, 2013).

- Best Poster Presentation Award, MagNET AGM, University of Waterloo, June, 2012.

- Concordia University Partial Tuition Scholarship for International Students (September 1, 2011 to August 31, 2012).

- Ministry of Higher Education. Excellent student award (2004), Baghdad, Iraq.

Teaching Experience

1- Winter Semester 2013/2014

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 321 (Properties and Failure of Materials) course.

2- Fall Semester 2013/2014

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 221 (Materials Science) course.

3- Winter Semester 2013:

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 321 (Properties and Failure of Materials) course.

4- Fall Semester 2012/2013

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 221 (Materials Science) course.

5- Winter Semester 2012:

Working for Concordia University, Department of Mechanical Engineering, as TA Leader and marker for MECH 321 (Properties and Failure of Materials) course.

6- From 1/10/2009 to 1/6/2010 (1st and 2nd semesters of 2009/2010):

Working for University of Jordan / Faculty of Engineering and Technology / Department of Industrial Engineering as an assistant teacher in the manufacturing processes laboratory. The taught topics involved: metal casting, wear of metals, mechanical behavior, rolling of metals, deep drawing, blanking and piercing of sheet metals, and extrusion of metals.

Work Experience

1- From 1/8/2009 to 12/01/2011:

Working for Qaraman Co. for Bolts and Spare Parts Ltd. as:

Manager of steel heat treatment department.

2- From 1/9/2007 to 1/7/2009:

Working for Al-Balqa for Metals and Tools Co. as:

i. Technical Manager with the following duties.

- Technical Support for BOHLER special steels (Steel selection & steel heat treatment).

- Marketing of BOHLER special steels.

3- From 1/7/2006 to 31/8/2007:

Working for Al-Hijaz Engineered Machining Establishment with its sister company (National Industrial Rehabilitation Company - NIRCO) as:

i. Marketing engineer of BELZONA products.

ii.Mechanical designer using AutoCAD.

4- From 20/11/2004 to 28/2/2006:

Working for SHEBA Metal Casting Company as:

i. Production engineer

ii. Heat treatment furnace operator.

iii. Patterns designe using AutoCAD software.

iv. Preparing daily reports explaining melting and heat-treatment procedures.