CO2 Utilization and sequestration

Reduce the cost of decarbonization in the industrial sectors by developing and optimizing innovative, large-scale CCUS processes to enable secure carbon capture and utilization options that make CO2 conversion as a business case.

PROJECTS

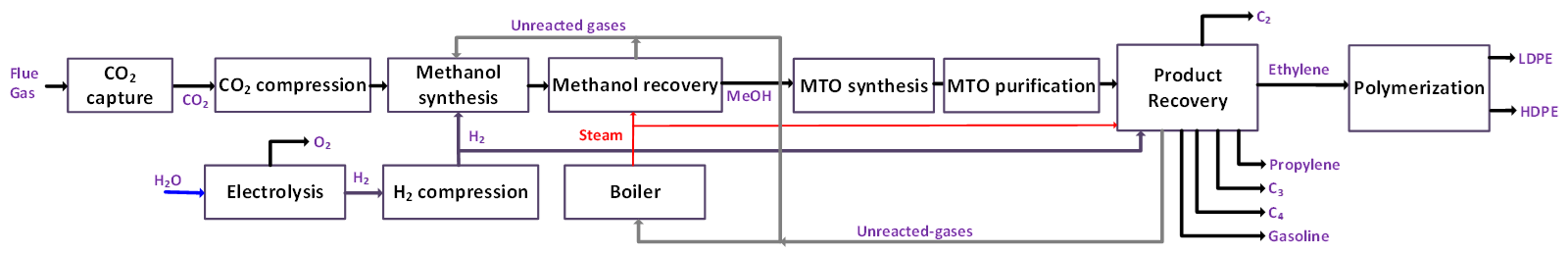

Development and Life cycle assessment of the CO2 capture and utilization for polyolefins production via MTO process.

The typical manufacture of LDPE and HDPE generates large greenhouse gas emissions (1.92 and 1.86 kg CO2/kg of polymer, respectively). Farah Mufarrij is designing alternative, carbon-negative paths for polymer manufacturing based on CO2 capture and utilization (CCU). The suggested routes for CCU-polymers are based on the conversion of CO2 to methanol, followed by the methanol-to-olefins (MTO) process to create primarily ethylene, and from ethylene, LDPE and HDPE. The findings of the LCA demonstrated that the CCU-MTO route is an environmentally preferable alternative, especially in locations where renewable (low-carbon) power is available.

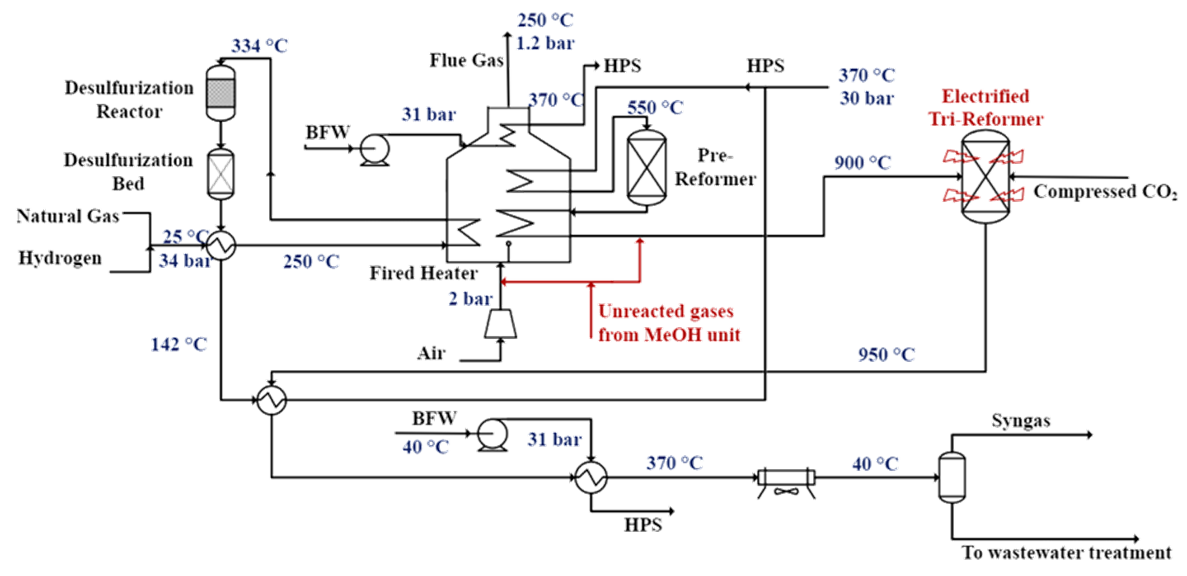

Electrification of Tri-reforming process for more efficient CO2 utilization

Khadijeh Barati is working on the process development and environmental impact assessment of a novel electrified Tri-reforming technology for the efficient co-conversion of CO2 and natural gas for the production of syngas and its utilization for methanol production.